Creating high-performance, eco-friendly ground vehicles requires balancing fuel efficiency, performance, and emissions. This research integrates hybrid electric vehicle simulations with detailed engine modules to enhance prediction accuracy and support design studies. A novel methodology combines vehicle and engine simulations, enabling optimized design for minimal fuel consumption and maximal performance.

The drive for eco-friendly vehicle designs is fueled by government regulations and industry recognition of growing public awareness. The Partnership for the Next Generation of Vehicles (PNGV) is a collaborative effort between the US government and major automotive manufacturers to develop sustainable vehicles. With the inevitability of alternative powertrains, the industry is investing in new technologies for high-mileage, non-polluting vehicles. To streamline product development, physically based computer simulations are used to evaluate the impact of new technologies on overall vehicle design [1]. Under the PNGV program, specific design requirements have been established as targets. By combining simulation models with mathematical optimization techniques, the design space can be explored within these constraints, yielding valuable insights for system improvement.

Conventional internal combustion engine powertrains have limitations, including overdesign, suboptimal operation, and inability to optimize across all speed and load ranges. Hybrid electric powertrains offer a solution by decoupling the engine from peak demands, reducing engine size requirements. A hybrid electric vehicle (HEV) combines at least two propulsion sources, one being electric, with various configurations possible [2]. The design process requires a system engineering approach, evaluating component contributions to overall system performance. Trade-offs between component sizes, fuel economy, and performance are assessed to achieve optimal design [3].

Effective optimization of hybrid electric vehicles (HEVs) relies on high-quality system simulations and robust optimization algorithms. While existing literature focuses on conventional powertrains, HEV research has primarily explored parametric studies for component sizing and energy management. Notable studies include Moore’s spreadsheet-based approach for sizing powertrain components, Zoelch and Schroeder’s dynamic optimization for optimal torque and gear ratios, and Bumby and Forster’s direct search technique for energy minimization [4].

This paper presents a methodology for HEV design optimization, utilizing mathematical models and simulations to represent components and subsystems. The approach leverages optimization algorithms to iterate towards the best design according to specified criteria and constraints. The methodology is built upon the ADVISOR vehicle simulation program, enhanced with a high-fidelity turbocharged diesel engine simulation code (TOES). The integrated ADVISOR-TOES simulation is coupled with optimization algorithms to create a system design tool.

The tool is used to study the impact of component sizing on fuel economy and performance, with design variables including diesel engine displacement, battery pack capacity, and motor power rating. Design objectives and constraints are set according to PNGV guidelines. Engine-scaling techniques based on TOES enhance the flexibility and predictive ability of HEV simulation. The implementation utilizes a distributed computing environment to accelerate simulations [5].

The paper outlines the engine and vehicle models used, including ADVISOR, TOES, and the integration of TDES and ADVISOR. The optimization methodology and results are then presented, followed by concluding remarks [6].

Various computer programs simulate hybrid electric powertrains and vehicles, categorized into feed-backward and feed-forward configurations. Feed-backward simulations start with required torque at the tire, while feed-forward simulations begin with driver demand, resembling real-life situations. Notable feed-backward software tools include SIMPLEV, CarSim, HVEC, CSM HEV, V-Elph, and ADVISOR.

ADVISOR, a MATLAB/SIMULINK-based feed-backward simulation, analyzes performance, emissions, and fuel economy of conventional, electric, and hybrid vehicles. Component models in ADVISOR are empirical, relying on input-output relations from laboratory data. The engine model uses look-up tables from steady-state tests, while electric motor and battery modules contain efficiency maps and functional relationships. ADVISOR accounts for dynamics and rotational inertia, allowing estimation of transient effects [7].

The SIMULINK model starts with driving cycle data, followed by blocks calculating vehicle velocity, load, engine and motor requirements, fuel usage, and battery state of charge. ADVISOR offers various component modules, but its fixed list may limit design engineers. To address this, ADVISOR includes routines for varying component size through scaling of maps. However, powertrain components do not scale well outside a narrow range due to nonlinear processes, prompting the replacement of the engine block and linear scaling routines in ADVISOR.”

TDES is a modified version of the turbocharged diesel engine simulation developed by Assanis and Heywood. The thermodynamic model combines quasi-steady flow models of engine components with a zero-dimensional diesel reciprocator model, enabling complete engine system simulation. A wastegate valve model is implemented, and the code provides flexibility regarding engine size and auxiliary subsystems. The diesel four-stroke cycle is treated as a sequence of continuous processes, with combustion modeled as a uniformly distributed heat-release process [8]. The dynamics of the wastegate valve can be described by the following differential equation: \[m \ddot{z} + b \dot{z} + S z = (p_1 – p_2) A_{\text{valve}} – (p_3 – p_4) A_{\text{diaphragm}} – F_{p,\text{spring}}\tag{1}\] where: \[\begin{aligned} z &= \text{wastegate valve lift} \\ m &= \text{mass} \\ b &= \text{damping constant} \\ S &= \text{spring stiffness} \\ p_1, p_2, p_3, p_4 &= \text{pressures at locations defined by their subscripts} \\ A_{\text{valve}} &= \text{valve head diameter} \\ A_{\text{diaphragm}} &= \text{diaphragm diameter} \\ F_{p,\text{spring}} &= \text{spring preload force} \end{aligned}\]

The interaction between the master cylinder model and other components is accounted for in manifolds, with instantaneous mixing of mass flows. Turbomachinery performance is defined by maps, and turbocharger dynamics are controlled by the balance of turbine and compressor torque, rotor inertia, and damping. The wastegate valve is boost pressure controlled, with valve dynamics taking into account pressure, spring force, and pressure difference [4,5].

The input data file is configured for a baseline engine, the 1.9L Volkswagen TDI diesel, with turbocharger maps supplied by Allied Signal and baseline engine test data obtained from MARCO for validation. The prediction of system parameters, such as engine performance and emissions, is enabled through this simulation.”

A generic, CORBA-based, object-oriented design framework is utilized for the design study of a parallel hybrid electric propulsion system. This framework supports distributed and heterogeneous computer resources, custom and existing simulation codes, various optimization algorithms, and easy reconfigurability of the design problem. A preliminary study was conducted using ADVISOR and its default scaling routine to understand the effects of component sizing on overall vehicle performance and fuel economy. The simulations act as implicit mathematical functions relating these quantities, with response surfaces. These surfaces depict trade-offs between system responses and design variables [8].

To determine proper finite difference step sizes for gradient approximations, a preliminary study was necessary. Figure 13 shows a zoom-in of the fuel economy response surface, depicting numerical noise due to numerical round-off, interpolation inaccuracy, or discrete events. A finite difference step of 0.2 kW was chosen to allow gradient-based algorithms to adequately sample the functions.

The design problem is formulated as a component sizing problem, with design variables including engine, motor, and battery rated power. Simple bounds are imposed on these design variables based on engineering judgment to adhere to packaging limitations.

Two design optimization problem formulations are chosen for the study. The first formulation maximizes fuel economy subject to performance constraints, while the second formulation minimizes 0-60 mph acceleration time while maintaining a high fuel economy and satisfying performance constraints.

The driving schedule selected to evaluate fuel economy is the SAE Cycle J 1711, which runs the vehicle through urban and highway schedules. A linear interpolation estimates charge-neutral fuel economy, accounting for energy supplied by the batteries.

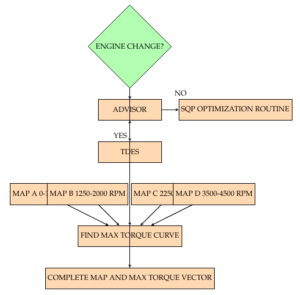

The optimization procedure showing the optimization loop implemented using the design framework. The schematic links the optimization routine and HEV simulations to evaluate design objective and constraint functions at each new design point generated by an optimization iteration.

| **Constraint** | **Value** | **Unit** |

| Fuel economy | $$\geq 45$$ | mpg |

| 0-60 passing time | $$\leq 5.3$$ | sec |

| Maximum speed | $$\geq 85$$ | mph |

| 0-85 time | $$\leq 23.4$$ | sec |

| 5-sec distance | $$\geq 140$$ | ft |

| Maximum acceleration | $$\geq 0.5$$ | g’s |

| Cruising grade | $$\leq 6.5$$ | % at 55 mph |

The gradient-based sequential quadratic programming (SQP) optimization algorithm was employed as the search engine within the framework. At each iteration, the SQP algorithm generates a new design point that enhances the objective function while reducing constraint violations. Iterations continue until convergence to a local optimum. To address the potential for local optima, multiple optimization runs from diverse starting points were performed. A design of experiments approach was used to select starting points, and two function evaluation schemes were implemented using ADVISOR and ADVISOR+TDES.

The optimization process was distributed across four computer workstations for concurrent processing, resulting in a fourfold decrease in runtime. The 40-60 mph passing time constraint was always active, indicating its criticality to the optimum design. The optimizer identified the smallest engine size that meets the passing time requirement, with the electric motor and battery sized to assist the engine during acceleration.

Additional optimization iterations were performed using ADVISOR+TOES, which provided higher fidelity engine performance prediction but increased computational time. The optimum configuration was determined, and comparison with results from ADVISOR showed small differences in fuel economy and component size. The improvement in accuracy did not justify the increased computational cost, likely due to the small engine size and medium speed and load operation during the SAE driving cycle.

In a comprehensive optimization study, finding the optimum for an initial problem statement and design specifications is typically the first step. Alternative problem statements and parametric studies can provide valuable insights for design engineers and management.

A previous study identified a small engine with large electrical components as optimal for fuel economy. An alternative problem statement was explored, minimizing 0-60 mph time while imposing a 45-mpg fuel economy constraint. This study demonstrates how changing the design goal impacts optimum component sizes.

| Run # |

Motor

(kW) |

Battery

(kW) |

Engine

(kW) |

Fuel economy

(mpg) |

40-60

passing time (sec) |

Activity |

| 1 | 38.2 | 49.5 | 30.4 | 48.5 | 10.2 | -0.0012 |

| 2 | 35.9 | 43.2 | 37.1 | 46.3 | 11.5 | 0 |

| 3 | 23.5 | 28.9 | 48.2 | 41.9 | 12.8 | -0.0419 |

| 4 | 40.1 | 51.3 | 30.5 | 48.6 | 10.1 | 0 |

| 5 | 36.4 | 45.6 | 31.2 | 47.2 | 10.9 | 0 |

| 6 | 34.8 | 44.1 | 31.5 | 46.8 | 11.2 | 0 |

| 7 | 24.9 | 30.5 | 45.9 | 42.5 | 13.1 | -0.0291 |

| 8 | 37.3 | 47.2 | 30.8 | 48.1 | 10.4 | 0 |

| Run # | Motor (kW) | Battery (kW) | Engine (kW) | 0-60 mph time (s) | 45-mpg activity |

| 1 | 25.1 | 38.4 | 42.9 | 11.2 | -0.8543 |

| 2 | 82.5 | 105.6 | 31.9 | 8.1 | -0.0121 |

| 3 | 67.3 | 92.1 | 34.2 | 8.5 | -0.0492 |

| 4 | 58.9 | 81.4 | 36.5 | 9.0 | -0.0234 |

| 5 | 31.7 | 43.8 | 40.1 | 10.8 | 0.0125 |

| 6 | 95.6 | 109.2 | 29.4 | 8.2 | -0.9821 |

| 7 | 88.2 | 59.3 | 33.1 | 10.3 | -0.7532 |

| 8 | 102.8 | 28.5 | 94.2 | 8.6 | -0.5219 |

Using ADVISOR default scaling and multistart optimization, solutions were obtained with 0-60 times ranging from 7.9 to 10.3 seconds. The optimal designs differed significantly from those obtained for fuel economy optimization, with larger engines and battery packs near the upper bound. Averaging the best combinations yielded a HEV specification with a 72-kW motor, 99-kW battery, and 36-kW engine.

Multistart results provided valuable comparisons, as some local optima offered more practical motor and battery combinations. For example, one solution had a 34.4-kW motor and 41.1-kW battery, with a 0-60 time of 10.1 seconds and 45.7 mpg fuel economy. Optimization algorithms identified mathematically optimal solutions, but designers may prefer alternative solutions.

Using ADVISOR+TDES, the best solution was optimized further, converging to a point with a 75.1-kW motor, 97.2-kW battery, and 34.2-kW engine. This solution was relatively close to the previous one obtained using ADVISOR default scaling.

The results from the two problem statements demonstrate the impact of changing the design objective on the optimal component sizes. The fuel economy optimization yielded a small engine with large electrical components, while the acceleration time optimization resulted in a larger engine with even larger electrical components.

The multistart optimization technique proved valuable in both studies, as it identified multiple local optima and provided a range of solutions for the designer to consider. The use of ADVISOR+TDES further refined the optimal solutions, providing more accurate predictions of component performance.

The studies provide several insights for the design of hybrid electric vehicles. First, the choice of design objective has a significant impact on the optimal component sizes. Second, the use of multistart optimization and advanced simulation tools like ADVISOR+TDES can help identify more practical and efficient solutions. Finally, the results highlight the trade-offs between fuel economy and acceleration performance, and the need for designers to consider multiple objectives when optimizing vehicle performance.

Future studies could explore additional problem statements and design specifications, such as minimizing cost or maximizing durability. The use of more advanced optimization algorithms and simulation tools could also provide further insights and improvements in hybrid electric vehicle design.

In conclusion, the optimization studies presented in this research demonstrate the importance of careful consideration of design objectives and constraints in the development of hybrid electric vehicles. The two problem statements, focusing on fuel economy and acceleration time, respectively, yielded distinct optimal component sizes and highlighted the trade-offs between competing objectives.

The use of multistart optimization and advanced simulation tools like ADVISOR and ADVISOR+TDES proved invaluable in identifying multiple local optima and refining the optimal solutions. The results provide valuable insights for designers, highlighting the need to consider multiple objectives and constraints when optimizing vehicle performance.

The studies also underscore the importance of careful selection of design variables and constraints, as well as the need for robust optimization algorithms and simulation tools. The results suggest that a comprehensive optimization approach, incorporating multiple problem statements and advanced simulation tools, can lead to more efficient and effective hybrid electric vehicle designs.

Furthermore, the research highlights the potential for optimization techniques to inform design decisions and improve vehicle performance, while also considering factors like cost, durability, and marketability. Future studies could build on these findings, exploring additional problem statements and design specifications, and leveraging more advanced optimization algorithms and simulation tools to further improve hybrid electric vehicle design.

Overall, this research demonstrates the power of optimization techniques in hybrid electric vehicle design, and highlights the need for a comprehensive and multifaceted approach to optimizing vehicle performance. By carefully considering design objectives, constraints, and variables, and leveraging advanced simulation tools and optimization algorithms, designers can create more efficient, effective, and sustainable hybrid electric vehicles.