The erosion performance of ion-nitrided S48C carbon steel, pure titanium, and Ti6Al4V alloy was evaluated under simulated solid-liquid impact conditions. The results demonstrated that ion nitriding substantially enhanced the erosion resistance of S48C steel. In contrast, the erosion behavior of titanium and Ti6Al4V alloys exhibited minimal improvement due to factors such as limited case depth and the formation of a brittle surface layer. It is proposed that the increased hardness imparted by the nitriding process contributes to improved energy dissipation during particle impact, thereby reducing material loss.

High-speed impacts from liquid or solid particles, or even a combination of both (synergistic erosion), are a major contributor to wear and tear in machine components found in hydraulic power plants, mining equipment, and jet engines. Since the 1960s, extensive research has been conducted on understanding and mitigating solid-liquid erosion. The key factors influencing this type of erosion are identified as particle size, velocity, impact angle, and the material properties itself. Notably, ductile metals tend to experience peak erosion rates at impact angles between 15 and 30 degrees, while brittle materials exhibit maximum erosion at normal impact (90 degrees).

One of the most challenging scenarios for material erosion involves high temperatures coupled with high-velocity particle impacts [1]. A significant portion of erosion research focuses on improving material resistance to these harsh conditions. Recent advancements have explored specialized material selection and surface engineering techniques to enhance erosion resistance [2-4]. Surface engineering offers a cost-effective approach compared to material selection, potentially avoiding issues like reduced workability and machinability associated with switching materials. Common surface engineering methods include elastomeric coatings [5], hard coatings, laser cladding, thermal spraying, and nitriding [6].

Among these methods, ion nitriding presents several advantages: it minimizes dimensional changes in treated parts, achieves uniform surface hardening, and promotes excellent adhesion of the surface layer [7]. Previous research has primarily focused on the erosion behavior of individual materials. This study aims to bridge this gap by exploring and comparing the solid-liquid erosion behavior of typical structural materials after ion nitriding treatment. S48C medium carbon steel, pure titanium, and Ti6Al4V alloy were chosen as the substrates for this investigation.

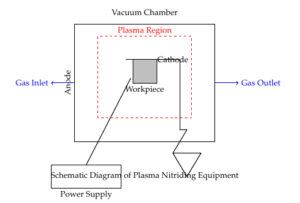

S48C (AISI 1042) medium carbon steel, pure titanium, and Ti6Al4V alloy were machined into plate-shaped specimens measuring 2 cm by 1.5 cm by 0.3 cm. Both sides of each specimen were meticulously polished to a mirror-like finish with an average surface roughness of Ra = 0.02 \(\mu\)m. A subset of these specimens underwent ion nitriding in a specialized furnace (Fig. 1), under the conditions outlined in Table 1. To compensate for the lower nitrogen diffusivity in titanium-based metals, a higher cathode voltage was applied during the nitriding process for pure titanium and Ti6Al4V to maintain an adequate nitriding temperature.

| Condition | S48C | Ti and Ti6Al4V |

|---|---|---|

| Nitriding time (h) | 20.0 | 3 |

| Nitriding temperature (◦C) | 350 | 275 |

| Total gas flow rate (sccm) | 20 | 20 |

| N\(_2\)/(H\(_2\) + N\(_2\)) (%) | 42.5 | 20.0 |

| Working pressure (Pa) | \(3.00 \times 10^2\) | \(7.65 \times 10^2\) |

| Cathode voltage (V) | 1400 | 900 |

| Cathode current (A) | 0.8 | 1.2 |

Vickers microhardness testing with a 0.49 N load was conducted to assess the hardness of both the substrate materials and the ion-nitrided specimens.

Erosion experiments were performed in a modified testing apparatus at room temperature, adhering to the ASTM G32-85 standard. Water, pressurized and carrying silica erodent from an inlet tube, was directed at the specimen. A custom-designed turntable distributor ensured a consistent erodent feed rate. The erosion test parameters are summarized. Angular silica particles served as the erodent. The cumulative weight loss of the eroded specimens was recorded at various impact durations and angles using an electronic balance.

X-ray diffraction (XRD) was employed to characterize structural changes induced by ion nitriding. Scanning electron microscopy (SEM) and optical microscopy were utilized to examine the surface and cross-sectional morphology of the ion-nitrided specimens both before and after erosion testing.

| Material | Phase |

|---|---|

| S48C | \(\epsilon\)-Fe\(_3\)N, \(\gamma\)-Fe\(_4\)N |

| Ti | TiN, Ti\(_2\)N |

| Ti6Al4V | TiN, Ti\(_2\)N, Ti\(_2\)AlN |

The cross-sectional microstructures of the nitrided specimens revealed a distinct compound layer atop a darker diffusion zone for all samples. The compound layer and diffusion zone were thinner in pure titanium and Ti6Al4V due to the lower nitrogen diffusivity in titanium-based alloys, despite higher nitriding temperatures and extended times.

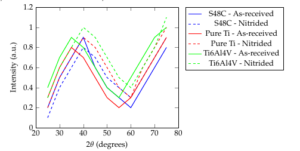

XRD analysis (Fig. 2,) identified the phase composition of the nitrided layers. S48C exhibited an \(\epsilon\)-Fe3N/\(\gamma\)’-Fe4N/\(\gamma\)-Fe(N)/\(\alpha\)-Fe structure, while pure titanium displayed a \(\gamma\)-TiN/\(\epsilon\)-Ti2N/\(\alpha\)-Ti(N)/\(\alpha\)-Ti configuration. Ti6Al4V contained \(\gamma\)-TiN/\(\epsilon\)-Ti2N/Ti2AlN/\(\alpha\)-Ti(N)/(\(\alpha\) + \(\beta\))-Ti-6Al-4V phases. The compound layer thickness of S48C was approximately 20 \(\mu\)m, whereas it was around 5 \(\mu\)m for both titanium-based materials.

Hardness measurements showed significant increases after nitriding, primarily attributed to the formation of the hard compound layer. Nitrided S48C achieved a hardness of Hv600.0, while nitrided pure titanium and Ti6Al4V reached Hv1579.4 and Hv1712.4, respectively.

The appearance of the eroded specimens indicated that the hard compound layer effectively resisted particle impact, confining damage to a smaller area compared to the untreated samples. The formation of a “comet’s tail” feature at lower impact angles was indicative of typical solid-liquid erosion.

Cumulative weight loss analysis revealed a near-linear relationship between weight loss and erosion time for both untreated and nitrided titanium. The nitrided samples exhibited a longer incubation period, suggesting delayed erosion initiation.

Crater depth measurements confirmed the strong influence of impact angle on erosion damage. S48C, despite a shallower crater due to higher density, exhibited the highest weight loss in the untreated condition. Nitriding significantly reduced crater depth and weight loss for S48C [8].

Two primary erosion mechanisms were identified: plastic deformation at low impact angles and indentation/extrusion damage at higher angles. The nitriding layer effectively mitigated plastic deformation due to its high hardness, resulting in lower weight loss at low impact angles [9]. At high impact angles, brittle fracture of the compound layer limited the protective effect of nitriding for titanium-based materials.

S48C demonstrated higher erosion susceptibility but exhibited a more significant improvement with nitriding compared to titanium-based materials [10]. This was attributed to the thicker nitriding layer and potentially higher fracture toughness of iron nitrides. While titanium alloys offer intrinsic hardness advantages, the thin nitriding layer limited their erosion resistance [11].

Ion nitriding effectively enhanced the erosion resistance of S48C steel through the formation of a thick, hard compound layer. For titanium-based alloys, the benefits of nitriding were more limited due to thinner compound layers and potential brittle fracture. A balance between hardness and ductility is crucial for optimal erosion resistance.