A novel ECAP procedure was conducted on 6061 aluminum sheet at temperatures up to 513K to investigate the temperature effect on microstructure and texture formation. The results show that at low temperatures (below 433K), the microstructure is characterized by high dislocation density within subgrains with thick, waved non-equilibrium boundaries, and the textures are characterized by a rotated cube component or similar components

({031}(513),{013}(513),{041}(614),{014}(641)). At high temperatures (513K), the microstructure shows low dislocation density subgrains separated by regular boundaries, with a preferable (1 1 1)ND texture fiber formation and a high R-value (up to 1.5). The ECAP procedure has potential applications to enhance the formability of aluminum sheets.

The development of techniques for applying severe plastic deformation (SPD) to ductile metals and alloys has been a significant area of research in recent years. Among these techniques, equal-channel angular pressing (ECAP) has emerged as a promising method for refining microstructures and enhancing mechanical properties without significant compositional modification. The ECAP process involves imposing high levels of strain on the material, leading to the creation of a submicron or nano-size grain structure. This process has been widely used to improve the mechanical properties of bulk materials with circular or square cross-sections. However, the conventional ECAP methods have limitations when it comes to processing sheet metals, which are increasingly used in the automotive industry to improve fuel efficiency and reduce vehicle emissions. To address this limitation, a novel ECAP-based process has been developed, enabling the continuous processing of sheet metals. This process has the potential to induce simple shear strain in aluminum sheets, promoting their formability. Despite its potential, the effect of temperature on microstructure and texture formation in aluminum sheets during the ECAP process remains unexplored, particularly in relation to sheet formability. Therefore, this study aims to investigate the microstructure and texture evolution of 6061 aluminum sheets at different ECAP temperatures, shedding light on the underlying mechanisms and their impact on sheet formability [1-5].

The increasing demand for fuel-efficient and environmentally friendly vehicles has led to a growing interest in the use of lightweight materials, such as aluminum alloys, in the automotive industry. Aluminum sheets, in particular, offer a promising solution due to their high strength-to-weight ratio, corrosion resistance, and formability. However, the formability of aluminum sheets is highly dependent on their microstructure and texture, which can be influenced by various processing parameters, including temperature.

The ECAP process has been shown to be effective in refining the microstructure of aluminum alloys, leading to improved mechanical properties. However, the majority of previous studies have focused on the ECAP of bulk materials, with limited research on the processing of sheet metals. Moreover, the effect of temperature on the microstructure and texture evolution of aluminum sheets during the ECAP process remains unclear. Temperature is a critical parameter in the ECAP process, as it can significantly influence the deformation mechanisms, microstructure evolution, and resulting texture. Understanding the impact of temperature on the ECAP process is essential for optimizing the microstructure and texture of aluminum sheets, ultimately enhancing their formability.

This study aims to bridge the knowledge gap by investigating the effect of temperature on the microstructure and texture formation of 6061 aluminum sheets during the ECAP process. The results of this research will provide valuable insights into the underlying mechanisms and will contribute to the development of optimized processing conditions for improving the formability of aluminum sheets.

The procedure begins with warm rolling of 6061 aluminum plates (5 mm thickness) unidirectionally with 10-15% reduction per pass, repeated without intermittent annealing until a final thickness of 1.55 mm is reached. Next, the rolled strips are cut into dimensions of 20 mm × 200 mm × 1.55 mm. The strips are then placed in a furnace at the required temperature (room temperature, 353 K, 433 K, or 513 K) and held for 30 minutes. After heating, the strips are quickly fed into the ECAP apparatus and subjected to ECAP at a speed of 40 m/s.

Following ECAP, microstructure examination is conducted by cutting TEM samples from the side plane of the strips, grinding them mechanically to 40 \(\mu m\), and then ion milling to perforate a hole. Microstructure observations are taken using a Hitach-800 TEM at 175 kV, and SEAD patterns are obtained from the region of the nearest \(\{1 1 1\}\) zone.

For texture evaluation, specimens are cut from the ECAPed strips and thinned chemically to half thickness. The \(\{1 1 1\}\), \(\{2 0 0\}\), and \(\{2 2 0\}\) pole figures are measured using an automated X-ray goniometer, and the ODFs are calculated from the pole figures using the WIMV method. Finally, R-values are calculated using the popLA program to evaluate the formability associated with each texture.

The microstructure of 6061 aluminum sheets subjected to ECAP at different temperatures was examined using TEM and SAED. At room temperature, the microstructure was characterized by thick and waved non-equilibrium grain boundaries and high dislocation density within cells and subgrains. Similar microstructures were observed at 353 K and 433 K, with elongated fine subgrains and non-equilibrium grain boundaries. However, at 513 K, the microstructure changed significantly, with thin and regular-shaped cell boundaries and reduced dislocation density. This suggests that dynamic recovery may occur at this temperature due to the high stacking fault energy of aluminum.

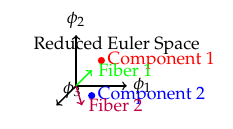

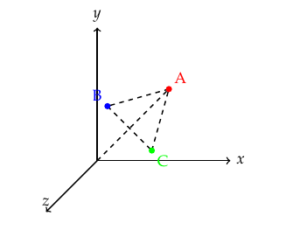

The textures formed at different temperatures were also investigated. At room temperature, the texture was characterized by the Rotated cube component and a minor \(1 1 2\) component. No significant texture change was observed at 353 K and 433 K. However, at 513 K, the texture changed remarkably, with the maximum intensities shifted to the position of the \(3 3 2\) component, indicating a transition to a fiber texture. The maximum orientation intensities were kept at a level of eight times the random intensity, indicating that the same ECAP shear strain was induced in each of the aluminum sheets [5].

The impact of texture on sheet formability was evaluated by calculating the R-values. The R-values were found to be 1 or below 1 for samples ECAPed at room temperature, 353 K, and 433 K. However, the sample ECAPed at 513 K demonstrated a higher R-value of 1.5, indicating improved formability. This is attributed to the formation of the fiber texture, which is favorable for sheet forming. The results suggest that ECAP can be used to control the texture of aluminum sheets and enhance their formability [6].

The results of this study demonstrate that the ECAP process can be used to control the texture of 6061 aluminum sheets and improve their formability. The formation of the fiber texture at 513 K is particularly noteworthy, as it is a favorable texture for sheet forming. The R-value of 1.5 obtained at this temperature indicates improved formability, making it suitable for applications requiring high formability [7-9].

The microstructure and texture evolution observed in this study can be attributed to the combined effects of ECAP shear strain and temperature. The high shear strain induced by ECAP leads to the formation of non-equilibrium grain boundaries and high dislocation density, which can be reduced by increasing the temperature. The dynamic recovery observed at 513 K is likely due to the high stacking fault energy of aluminum, which enables the annihilation of dislocations and the rearrangement of grain boundaries.

The findings of this study have important implications for the processing of aluminum alloys. The ability to control texture and improve formability through ECAP processing can lead to the development of new applications for aluminum alloys, particularly in the automotive and aerospace industries where high-strength and high-formability materials are required.

In conclusion, this study has demonstrated the effectiveness of ECAP processing in controlling the texture and improving the formability of 6061 aluminum sheets. The formation of the fiber texture at 513 K is a significant finding, and further research is needed to fully understand the mechanisms underlying this phenomenon. The results of this study have important implications for the processing of aluminum alloys and highlight the potential of ECAP processing as a means of improving the properties of these materials.