Investigating the friction properties of poly(acrylic acid) (PAAc) hydrogel under low load conditions in both air and water environments. The influence of environmental conditions, applied load, hydrogel water content, and surface morphology on the friction coefficient was examined using a ball-on-plate friction tester. Results demonstrate significantly lower friction coefficients in water compared to air. A decreasing trend in friction coefficient with increasing load was observed, particularly pronounced at low loads. Hydrogel water content was found to be directly correlated with friction, with higher water content leading to lower friction. The dimpled surface structure of PAAc hydrogel contributed to its low friction properties. The balance between mechanical and water contact at the hydrogel-slider interface is crucial for hydrogel lubrication.

Hydrogels hold immense potential in various biomedical applications, including drug delivery, biomimetic devices, contact lenses, and artificial organs. However, their efficacy in these applications is heavily influenced by their tribological properties, particularly friction and wear [1]. This study focuses on a critical yet under-explored aspect – the friction behavior of poly(acrylic acid) (PAAc) hydrogel under low load conditions in both air and water environments.

Conventional tribological research on hydrogels has primarily concentrated on high load scenarios relevant to artificial joints. Here, we address the knowledge gap by investigating the friction behavior of PAAc hydrogel under low loads, mimicking conditions encountered in micro-medical devices [2,3]. These devices require smooth operation with minimal friction for efficient and patient-friendly procedures.

Previous research has established that the friction and wear of hydrogels are influenced by various factors, including their molecular structure, water content, and surface topography. This study aims to elucidate the role of these factors, specifically:

Load: How does the applied load affect the PAAc hydrogel’s friction coefficient under low load conditions?

Environment: Does the surrounding medium (air or water) influence friction behavior?

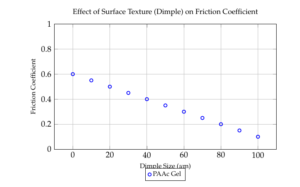

Surface Structure: Does the surface morphology of the PAAc hydrogel play a role in friction?

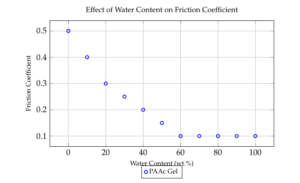

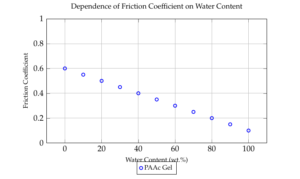

Water Content: How does the water content within the PAAc hydrogel affect its friction behavior?

By understanding these factors, we can explore strategies to optimize the friction properties of PAAc hydrogel for enhanced performance in micro-medical devices and other low-load biomedical applications.

PAAc hydrogels were synthesized via free radical polymerization of acrylic acid (AAc, Aldrich Chemical Company Inc., 99%) using ammonium peroxodisulfate (APS) as initiator and N,N-methylene-bisacrylamide (BIS) as crosslinking agent (both from Wako Pure Chemical Industries Ltd.). The AAc concentration ranged from 5 to 35 wt% in aqueous solution, while BIS content was fixed at 1 mol% relative to total monomers. Polymerization was conducted at 9 °C for 10 min followed by curing at room temperature (23 ± 2 °C) for 24h [2,4].

Glass substrates were cleaned using an ultrasonic bath with a benzene/ethanol (4:6) mixture followed by ultrapure water. To enhance hydrophobicity, one glass sheet was treated with chlorodimethylvinyl silane/hexane solution. The other sheet remained hydrophilic for comparison. Dimpled patterns were created on the hydrophilic glass [5].

Friction tests were performed using a ball-on-plate tribometer. A ball material, diameter, radius, hardness slider was used. Tests were conducted in air and ultrapure water at 23 ± 2 °C with a sliding velocity of 0.02 mm/s. Applied load ranged from 10 to 50 mN. Friction force was measured using a leaf spring and displacement sensor [6].

The load applied to a PAAc hydrogel is a critical determinant of its frictional behavior. As load increases, the hydrogel undergoes deformation, a process influencing the contact area between the hydrogel and the opposing surface. While augmented contact area might intuitively suggest increased friction due to enhanced adhesive interactions, the hydrogel’s unique properties introduce complexities [7].

A key factor is water expulsion. Under pressure, the hydrogel releases water towards its surface. This expelled water can act as a lubricant, mitigating frictional forces. However, the efficacy of this lubrication mechanism hinges on several variables, including the rate of water expulsion, the viscosity of the expelled fluid, and the interfacial characteristics between the water, hydrogel, and the opposing surface.

Hydrogel friction is also contingent upon the prevailing lubrication regime. Hydrodynamic lubrication, where a fluid film separates the surfaces, is challenging to achieve in hydrogels due to their porous nature [8]. Boundary lubrication, characterized by direct solid-solid contact, is more prevalent, especially under low loads and speeds. Mixed lubrication, a hybrid of the two, often dominates hydrogel systems.

The relationship between load and friction coefficient is not always linear. While increased load might reduce friction due to enhanced water-based lubrication, it can also increase friction through augmented contact area or induced structural changes within the hydrogel. Factors such as hydrogel composition, water content, and experimental conditions further complicate this relationship.

To accurately assess the influence of load, meticulous experimental design is essential. The load range should encompass the expected operational conditions. The loading rate, as hydrogels exhibit viscoelastic properties, can impact results. Environmental factors like temperature and humidity, as well as the characteristics of the opposing surface (roughness, material), influence friction. Additionally, the relative speed between the hydrogel and the opposing surface affects the lubrication regime and friction coefficient.

Understanding the intricate interplay between load, hydrogel deformation, water dynamics, and lubrication regime is crucial for optimizing hydrogel-based systems. Further research is imperative to elucidate the precise mechanisms governing the load-friction relationship in diverse hydrogel materials and operational conditions. This knowledge is essential for advancing applications in fields such as biomedicine, where the frictional behavior of hydrogels is paramount.

Water content is a paramount factor influencing the frictional properties of PAAc hydrogels. The presence of water within the hydrogel matrix significantly impacts its mechanical, physical, and interfacial characteristics, all of which contribute to friction.

Water acts as a plasticizer within the hydrogel network, reducing the polymer chain interactions and increasing the material’s flexibility. As water content rises, the hydrogel becomes more compliant, leading to increased deformation under load. This increased deformability can affect the contact area between the hydrogel and the opposing surface, influencing friction.

Water within the hydrogel can also function as an internal lubricant. Under shear stress, water molecules can reorient and form a lubricating film, reducing interfacial friction between polymer chains [9]. However, the effectiveness of this internal lubrication depends on factors such as water distribution within the hydrogel, the rate of shear, and the temperature.

In some cases, hydrogels incorporate additives such as surfactants or nanoparticles to modify their properties. Water acts as a carrier for these additives, influencing their distribution and effectiveness. For instance, if a surfactant is added to reduce friction, its concentration and distribution within the hydrogel, which are influenced by water content, will impact its performance.

The water content significantly affects the hydrogel’s three-dimensional structure. At high water contents, the polymer network is more open and porous, allowing for greater water mobility. Conversely, at low water contents, the network is denser, restricting water movement. These structural differences influence the hydrogel’s mechanical properties and, consequently, its frictional behavior [10].

The interfacial interactions between the hydrogel and the opposing surface are influenced by water content. A higher water content can lead to increased hydration of the hydrogel surface, potentially reducing adhesive forces with the opposing surface. However, excessive water can also create a hydrodynamic film, which can either reduce or increase friction depending on the specific conditions.

To accurately assess the influence of water content on hydrogel friction, careful experimental design is essential. Key factors include:

Water Content Range: A wide range of water contents should be tested to capture the full spectrum of behavior.

Hydrogel Preparation: Consistent hydrogel preparation methods are crucial to ensure reproducibility.

Testing Conditions: Parameters such as load, sliding speed, temperature, and humidity should be controlled.

Surface Characteristics: The properties of the opposing surface can influence the results.

The introduction of dimpled surfaces to hydrogels offers a potential avenue for manipulating frictional properties. By altering the surface topography, dimples can influence contact area, fluid retention, and shear stress distribution.

A primary effect of dimpled surfaces is the reduction of the apparent contact area between the hydrogel and the opposing surface. This reduction can significantly decrease adhesive forces, as the actual contact area is smaller. However, the effectiveness of this approach depends on the dimple geometry, including depth, width, and spacing.

Dimples can act as reservoirs for water or other fluids within the hydrogel. This fluid retention can enhance lubrication by providing a hydrodynamic cushion between the contacting surfaces. The depth and spacing of the dimples influence their ability to retain fluid. Additionally, the fluid’s viscosity and surface tension play a role in its effectiveness as a lubricant.

The presence of dimples can alter the distribution of shear stress across the hydrogel surface. By creating areas of stress concentration and relaxation, dimples can influence the deformation behavior of the hydrogel and the resulting frictional forces. The geometry of the dimples, as well as the applied load and sliding speed, will impact the shear stress distribution.

To effectively investigate the influence of dimpled surfaces, careful experimental design is essential. Key factors include:

Dimple Geometry: The depth, width, and spacing of the dimples should be varied to determine optimal parameters.

Dimple Coverage: The percentage of the surface covered by dimples should be considered.

Hydrogel Material: The properties of the hydrogel, such as elasticity and water content, will influence the dimpled surface’s performance.

Testing Conditions: Load, sliding speed, and environmental conditions should be controlled to isolate the effect of the dimpled surface.

While dimpled surfaces offer potential benefits for reducing friction, there are challenges to consider. For example, the manufacturing of consistent and precise dimple patterns can be complex. Additionally, the long-term stability of the dimples under frictional loading is a concern.

Despite these challenges, the potential benefits of dimpled surfaces make them an interesting area of research. By optimizing dimple geometry and hydrogel material, it may be possible to achieve significant reductions in friction while enhancing other hydrogel properties.

The frictional behavior of PAAc hydrogels is intricately linked to factors such as load, water content, and surface topography. Load influences hydrogel deformation, water expulsion, and the prevailing lubrication regime. Water content significantly impacts the hydrogel’s mechanical properties, acting as a plasticizer, lubricant, and carrier for additives. Dimpled surfaces offer potential for reducing friction by decreasing contact area, retaining fluid, and altering shear stress distribution.

Optimizing the frictional properties of PAAc hydrogels necessitates a comprehensive understanding of these interconnected factors. By carefully controlling load, water content, and surface topography, it is possible to design hydrogels with tailored frictional characteristics. Further research into the underlying mechanisms and the development of advanced characterization techniques are essential for unlocking the full potential of hydrogels in applications demanding specific frictional properties.

Ultimately, a deep comprehension of these factors will enable the creation of hydrogels with superior performance in a wide range of applications, from biomedical devices to industrial components.