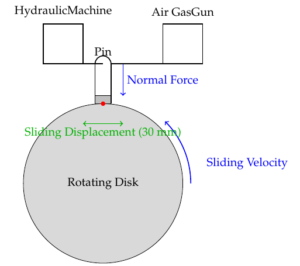

A novel experimental apparatus has been developed to investigate metal-on-metal dry friction under both static and dynamic regimes. Utilizing a custom-designed setup, high sliding velocities (ranging from 20 to 67 m/s) are achieved with a compressed air-powered system, while low sliding velocities (spanning 0 to 3 m/s) are facilitated by a hydraulic testing machine, both employing the same friction testing device. This study examines the influence of normal force and sliding velocity on frictional behavior.

Understanding friction phenomena is crucial for designing and extending the lifespan of machines and for modeling metal forming processes. For example, in high-speed machining (HSM), extreme contact conditions occur at the tool-chip interface, with high pressures and large sliding velocities (up to several tens of meters per second). Frictional effects cause intense heating at the tool-chip interface, reaching temperatures of over 900°C in the chip near the contact area [1].

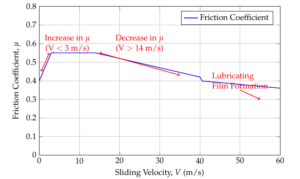

There is a growing interest in developing new experimental techniques to measure and simulate friction. Following this introduction, Section 2 reviews experimental devices used to study dry friction, focusing on the range of sliding velocities and normal force (or normal pressure). A novel device is presented, adapted for use on both a hydraulic machine and an air gas gun, enabling the determination of the friction coefficient \(\mu\) for both small and high sliding velocities. Reports experimental results for dry friction between metallic materials, validating our setup through a study of steel on steel dry friction. The results align with the data compilation [2], revealing two stages: an increase in friction coefficient with velocity (V < 3 m/s) and a decrease in friction coefficient with increased velocity (V > 14 m/s). The effect of normal pressure is also examined. Finally, Section 5 summarizes the conclusions of this work [3].

Many devices have been developed to investigate friction laws. Leonardo da Vinci was the first to propose an experimental setup for measuring friction. Later, Coulomb made a distinction between static friction, the force required to start sliding, and kinetic friction, the force required to maintain it. Other researchers confirmed Coulomb’s results, but the velocity range was limited to a few meters per second. The dependence of the friction coefficient on sliding velocity was investigated by Bochet, who explored a range of 1-25 m/s. Sliding friction is a complex process influenced by various parameters, including normal force, sliding velocity, material properties, and surface roughness. Friction tests reveal that the dry friction coefficient depends not only on the intrinsic characteristics of the interfaces but also on the dynamic properties of the device used [4].

Several experimental setups have been developed to study friction, including the pin-on-disk apparatus, which consists of a contact between a pin and a rotating disk. This setup is commonly used for low normal pressures and small sliding velocities. Sophisticated high-speed pin-on-disk setups have been designed to obtain high pressures and velocities. Other devices, such as modified torsional Kolsky bars, pressure-shear plate impact, and spun steel ball grabbing, can generate higher velocities and normal pressures. These setups have been used to investigate friction in various applications, including cutting processes and machining [5].

Impact friction tests have been developed to understand dynamic contact between two pieces with an initial velocity at the moment of contact. Plate impact pressure-shear friction experiments can create high normal pressures, simulating local conditions in machining. Original experiments have been developed to study friction at very high speeds and light loads, using magnetically suspended steel balls and leaf springs to apply normal loads. These setups have been used to investigate frictional behavior of different metals and materials [1,3,4].

The primary findings on metal-on-metal dry friction can be thoroughly summarized as follows:

At relatively low velocities (approximately V < 1 m/s), the friction coefficient exhibits a strong dependence on the roughness of the surfaces in contact. This is attributed to the asperities on the surfaces creating adhering patches, akin to spot welds, which require deformation or shearing work to produce the frictional force.

At higher velocities (V > 1 m/s), the friction coefficient becomes increasingly dependent on both the velocity and the normal force applied. Specifically, the friction coefficient decreases with increasing velocity and normal force.

At extremely high velocities and normal forces, a lubricating film of melted material forms between the sliding surfaces, significantly reducing the friction coefficient to very low values.

The inherent complexity of the physical laws governing friction leads to a high degree of variability in measured friction coefficients, depending on the specific test equipment and laboratory conditions employed.

Existing experimental techniques have limitations regarding the range of sliding velocities, normal pressures, and sliding displacement that can be achieved. To address this, the present paper proposes a novel experimental setup capable of testing a broad spectrum of conditions, including:

Sliding velocities ranging from 0.01 m/s to 60 m/s

Normal pressures of up to 230 MPa

Sliding displacement of up to 30 mm and beyond

Compared to other experimental techniques, this setup offers several advantages, including:

A significantly larger sliding distance (30 mm) compared to pressure-shear plate impact experiments (250 \(\mu\)m)

The ability to maintain an almost constant normal force after a brief transient period (500 \(\mu\)s), allowing for the measurement of the friction coefficient without the influence of wear effects.

The experimental investigation of metal-on-metal dry friction revealed several key findings. Firstly, at low velocities (V < 1 m/s), the friction coefficient was found to be strongly dependent on the roughness of the surfaces in contact. This was attributed to the formation of adhering patches at the tips of asperities, which required deformation or shearing work to generate frictional force. As the velocity increased (V > 1 m/s), the friction coefficient became increasingly dependent on both the velocity and the normal force applied. Specifically, the friction coefficient decreased with increasing velocity and normal force. This was attributed to the heat generated during frictional sliding and the oxidation produced by the large temperatures generated.

The below figure illustrates the relationship between the friction coefficient and sliding velocity, highlighting the increase and decrease in friction coefficient at different velocity ranges.

At extremely high velocities and normal forces, a lubricating film of melted material formed between the sliding surfaces, significantly reducing the friction coefficient to very low values.

The results of this study also highlight the importance of considering the thermal effects of frictional sliding. The heat generated during frictional sliding can lead to changes in the material properties, such as softening or melting, which can in turn affect the frictional behavior. This is particularly important in high-speed or high-load applications, where the thermal effects can be significant. In addition, the results of this study demonstrate the need for careful control of the surface roughness and velocity in order to optimize the frictional behavior. This can be achieved through careful surface preparation and control of the operating conditions.

The below figure provides a schematic representation of the novel experimental device, including the pin-on-disk apparatus connected to both a hydraulic machine and an air gas gun.

The formation of a lubricating film of melted material at extremely high velocities and normal forces is a novel finding that has important implications for the design of mechanical systems. This phenomenon can be exploited to reduce the frictional forces and improve the efficiency of mechanical systems. However, it is also important to consider the potential drawbacks of this phenomenon. For example, the melted material can solidify and form a hard, abrasive layer that can increase the frictional forces over time. Therefore, careful consideration of the operating conditions and material properties is necessary to optimize the frictional behavior.

The results of this study are consistent with previous findings on metal-on-metal dry friction. The strong dependence of the friction coefficient on surface roughness at low velocities is well-documented. The formation of adhering patches at the tips of asperities is a key mechanism contributing to frictional force. The decrease in friction coefficient with increasing velocity and normal force is also consistent with previous studies. The heat generated during frictional sliding and the oxidation produced by the large temperatures generated are likely contributing factors to this phenomenon [2].

The formation of a lubricating film of melted material at extremely high velocities and normal forces is a novel finding. This phenomenon is likely due to the high temperatures generated during frictional sliding, which cause the metal surfaces to melt and form a lubricating film. The results of this study have important implications for the design and operation of mechanical systems involving metal-on-metal dry friction. The strong dependence of the friction coefficient on surface roughness and velocity highlights the need for careful control of these parameters in order to optimize system performance [4].

The decrease in friction coefficient with increasing normal force has important implications for the design of mechanical systems involving high loads. The formation of a lubricating film of melted material at extremely high velocities and normal forces highlights the need for careful consideration of the operating conditions in order to avoid unexpected changes in frictional behavior [5].

In conclusion, this study has provided new insights into the behavior of metal-on-metal dry friction. The strong dependence of the friction coefficient on surface roughness and velocity, as well as the decrease in friction coefficient with increasing normal force, are key findings with important implications for the design and operation of mechanical systems. The formation of a lubricating film of melted material at extremely high velocities and normal forces is a novel finding with important implications for the design of mechanical systems involving high loads and velocities.