Simulations were performed on batch annealing (BA) and continuous annealing (CA) processes for high-strength interstitial-free (IF) steel sheets. Using electron backscatter diffraction (EBSD), the study examined microtexture, grain boundary character distribution (GBCD), and secondary working embrittlement (SWE). Results reveal that cracks associated with SWE tend to form primarily at random boundaries, while low-angle and low-\(\Sigma\) CSL boundaries help resist crack propagation. It is suggested that an optimal GBCD, featuring a high prevalence of low-angle or low-\(\Sigma\) CSL boundaries and a more fragmented random boundary network, may reduce the ductile-to-brittle transition temperature (DBTT) in IF steels, thus mitigating their susceptibility to SWE.

The development of deep-drawable sheet steels is crucial for the automotive sector, with titanium and/or niobium alloyed extra-low carbon interstitial-free (IF) steels being pivotal materials. The nearly complete removal of carbon and nitrogen is intended to enhance forming properties. However, the absence of solute carbon at grain boundaries significantly reduces the bonding strength at these interfaces, often leading to intergranular brittle fracture during impact deformation of deeply drawn steel sheets at low temperatures. This issue is known as secondary working embrittlement (SWE) or cold-working embrittlement (CWE). This problem is particularly severe in phosphorus-added high-strength IF steels, where phosphorus segregation at the grain boundaries exacerbates the issue [1-6].

Microtexture refers to the texture measured at the microstructural scale. Unlike conventional macrotexture approaches, microtexture analysis provides detailed information about individual orientations within the material. This includes access to grain boundary geometrical parameters, which are critical for understanding material behavior [7-12].

Attention to grain boundary geometry is important because grain boundaries significantly influence the microstructural heterogeneity of polycrystalline materials, impacting their bulk properties, especially those related to deformation and fracture. Intergranular fracture, for example, is closely linked to the type and frequency of grain boundaries, a concept known as grain boundary character distribution (GBCD). The GBCD concept, developed from the coincidence site lattice (CSL) model by Watanabe, underpins the field of grain boundary engineering (GBE).

Advancements in analytical techniques, such as electron backscatter diffraction (EBSD), have greatly enhanced our understanding of GBCD. EBSD, a scanning electron microscopy technique, provides detailed local lattice orientations, misorientations, and microtexture information by analyzing electron backscatter Kikuchi diffraction patterns. This technique has become essential for both qualitative and quantitative characterization of deformed and recrystallized microstructures.

This paper investigates the microtexture, GBCD, and secondary working embrittlement of high-strength IF steels subjected to batch annealing (BA) and continuous annealing (CA) using EBSD. The primary objective is to explore the relationship between GBCD and SWE in IF steel sheets.

The study utilized a cold-rolled, 0.8 mm thick high-strength IF steel sheet with the following composition: 0.0016% C, 0.062% Ti, 0.012% Si, 0.24% Mn, 0.07% P, 0.0004% S, 0.036% Al, and 0.0022% N. Batch annealing (BA) and continuous annealing (CA) treatments were conducted using laboratory simulators. The annealing cycles for CA and BA are illustrated in Fig. 2. Following annealing, a skin pass elongation of 1.0% was applied to the sheets.

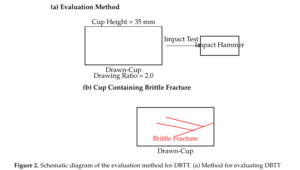

The ductile-to-brittle transition temperature (DBTT) was assessed using Charpy impact tests on drawn-cups with a height of 35 mm and a drawing ratio of 2.0, as shown in Fig. 1. The DBTT values obtained were \(-10^\circ\text{C}\) for BA sheets and \(-70^\circ\text{C}\) for CA sheets.

Samples from BA, CA, and drawn-cup specimens were selected for EBSD analysis. The specimen surfaces were polished with standard emery papers up to a 4000 grade, followed by electropolishing in a 5 vol.% perchloric acid solution at \(-40^\circ\text{C}\) with a voltage of 40 V. EBSD analysis was performed using a JEOL 6500F scanning electron microscope (SEM) equipped with an Oxford INCA Crystal EBSD system. The EBSD experiments were conducted at an accelerating voltage of 20 kV, with Kikuchi patterns integrated for 70 ms per analysis point, and up to 100 ms for drawn-cup specimens. An EBSD map with 256\(\times\)160 points at 400\(\times\) magnification, where each point covered an area of 2.05 \(\mu\)m\(^2\), was used for analyzing microtexture and grain boundary characteristics. Grain boundary classification followed the CSL model as described by Brandon’s formula :

\[\theta_m \leq 15^\circ \Sigma^{-1/2}\]

where \(\theta_m\) represents the maximum allowable deviation from perfect coincidence. In this study, boundaries were categorized as low-angle boundaries (\(\Sigma\)1 boundaries) if their misorientation angle, \(\theta\), was less than 15°, as low-\(\Sigma\) CSL boundaries if \(\theta\)-deviation was within \(\theta_m\) and \(\Sigma \leq 29\), and as other classifications based on the CSL model.

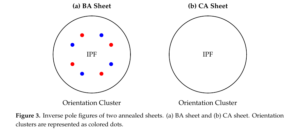

Fig. 3 displays the microstructure of the two annealed steel sheets as obtained through EBSP. The BA sheets exhibit a larger grain size compared to the CA sheets. Inverse pole figures (IPFs) for both BA and CA steel sheets, where 791 surface grains were analyzed. The IPF data indicate a higher concentration of orientations around the 111 pole in the ND (CA sheets) compared (BA sheets). This suggests that CA sheets have a greater number of grains with 111 planes aligned parallel to the sheet surface, resulting in a stronger 111 fibre (ND//111) texture compared to BA sheets. Additionally, the CA sheets exhibit a broader range of 111 fibre components, including 111110 and 111112, whereas the BA sheets primarily show the 111110 component.

A histogram of major orientation components for the surfaces of BA and CA sheets. The CA sheets show a 20% higher frequency of favorable grain orientations (i.e., 111 fibre) compared to the BA sheets. Conversely, the frequency of less favorable grain orientations (i.e., 110//RD fibre) is 10% higher in the BA specimens than in the CA specimens. This suggests that CA treatment enhances the deep drawability of IF steels due to the stronger 111 fibre texture.

The GBCDs obtained via EBSD for BA and CA steel sheets. Thin gray lines represent low-\(\Sigma\) CSL boundaries (1 \(\geq\) \(\Sigma\) \(\geq\) 29), while thick black lines denote random boundaries. The EBSD mapping shows that the BA sheet has a continuous network of random boundaries with a heterogeneous distribution of low-\(\Sigma\) CSL boundaries. In contrast, the CA sheet features a uniform distribution of low-\(\Sigma\) CSL boundaries, and the random boundary network is disrupted.

Histogram of grain boundary types for BA and CA sheets. The CA specimen has a 23% higher frequency of low-\(\Sigma\) CSL boundaries (1 \(\geq\) \(\Sigma\) \(\geq\) 29) compared to the BA specimen. Specifically, the CA sheet shows a higher occurrence of low-angle (\(\Sigma\)1), \(\Sigma\)3, and \(\Sigma\)13 boundaries, while \(\Sigma\)13 boundaries are less common in the BA sheet. The increased frequency of \(\Sigma\)13 CSL boundaries in the CA sheets is attributed to the stronger 111112 component, which enhances the formation of 30° 111 misorientations (\(\Sigma\)13b) between 111110 and 111112 orientations. Additionally, suggested that grain size influences the frequency of specific boundary types, with larger grains surrounded by high-angle random boundaries and smaller grains by low-angle or low-\(\Sigma\) coincidence boundaries.

The fracture morphology and surface of cracks observed at the root of the main crack face in deep-drawn cups (refer to Fig. 2b) from both BA and CA sheets. The BA specimens exhibit typical intercrystalline fractures, while the CA specimens display predominantly transgranular fractures. This aligns with the DBTT test results.

An EBSD map from a cracked area in the BA sheet, highlighting the GBCD around the cracks. It is apparent that cracks tend to initiate at random boundaries and do not propagate into regions with a higher density of low-angle or low-\(\Sigma\) CSL boundaries. This indicates that low-angle and low-\(\Sigma\) CSL boundaries offer resistance to crack propagation. Similar findings regarding the resistance of low-\(\Sigma\) CSL boundaries to cracking have been reported. These results suggest that intergranular fractures are more likely to occur at high-energy random boundaries, while low-energy boundaries like low-angle or low-\(\Sigma\) CSL boundaries are more resistant to fracture. The DBTT of BA sheets is higher than that of CA sheets due to the continuous random boundary network in the BA sheets, which tends to attract phosphorus and sulfur, reducing bonding strength at interfaces. High-energy boundaries are also more prone to interactions with glissile dislocations, leading to microcrack formation at these boundaries. Once a crack initiates, the continuous random boundary network facilitates its propagation. Schematically demonstrates the relationship between GBCD and the fracture process in polycrystalline materials, showing that a high fraction of random boundaries results in intergranular brittleness, whereas a lower fraction of such boundaries allows for mixed intergranular and transgranular fracture modes in a more ductile manner.

This study provides a comprehensive analysis of the effects of batch annealing (BA) and continuous annealing (CA) on the microtexture, grain boundary character distribution (GBCD), and secondary working embrittlement (SWE) of high-strength interstitial-free (IF) steel sheets. The findings can be summarized as follows:

Microstructure and Texture: The CA-treated steel sheets exhibit a finer grain size and a stronger 111 fibre texture compared to BA-treated sheets. This enhanced texture in CA sheets, characterized by a higher concentration of 111 planes oriented parallel to the sheet surface, contributes to improved deep drawability. The CA sheets show a 20% increase in the frequency of favorable 111 fibre orientations and a more diverse range of 111 fibre components compared to the BA sheets.

Grain Boundary Character Distribution: The GBCD analysis reveals that CA sheets have a more uniform distribution of low-\(\Sigma\) CSL boundaries and a disrupted random boundary network compared to BA sheets. The CA sheets exhibit a 23% higher frequency of low-\(\Sigma\) CSL boundaries, including \(\Sigma\)1, \(\Sigma\)3, and \(\Sigma\)13 types, which are associated with enhanced material properties. The BA sheets, conversely, show a continuous random boundary network with a heterogeneous distribution of low-\(\Sigma\) CSL boundaries.

Secondary Working Embrittlement: The analysis of fracture paths and surfaces indicates that SWE manifests differently in BA and CA sheets. The BA sheets predominantly exhibit intergranular fractures due to the continuous network of high-energy random boundaries, which are more prone to phosphorus and sulfur segregation. In contrast, CA sheets display transgranular fractures, attributed to the higher prevalence of low-angle and low-\(\Sigma\) CSL boundaries that resist crack propagation. This resistance is linked to the stronger 111 fibre texture and the uniform distribution of beneficial grain boundary types in CA sheets.

Overall, the CA treatment significantly enhances the formability and resistance to SWE of high-strength IF steel sheets compared to the BA treatment. The results underscore the importance of optimizing annealing processes to achieve desirable microstructural and textural characteristics that improve the mechanical performance and reliability of steel products in automotive applications.