Field inspection of civil infrastructure, such as bridges and buildings, is essential for ensuring safety, reliability, and effective maintenance. However, the development of field inspection support systems (FISS) has long been challenged by high costs, redundancy, and lack of reusability. This paper introduces the Java-Based Inspection Framework (JIF), a modular and customizable software framework designed to streamline the construction of field inspection support systems. By leveraging object-oriented design principles, JIF captures common components across inspection workflows, including inspection data collection, task management, and domain-specific knowledge. The framework reduces development time and enhances system reliability through reusable design patterns and XML-based scripting, enabling seamless integration with existing infrastructure management systems like Bridge Management Systems (BMS). A case study involving a bridge inspection system for the Pennsylvania Department of Transportation (PennDOT) demonstrates JIF’s applicability and benefits. Results show that JIF facilitates efficient customization, improves data collection accuracy, and simplifies the inspection process, making it a valuable tool for field inspectors and developers. Future enhancements include the development of graphical tools to further simplify user interaction and customization.

The maintenance, repair, and rehabilitation of civil infrastructure systems are critical components of sustainable development and public safety [1]. Civil infrastructure, including bridges, highways, buildings, and utility networks, represents a backbone of economic and societal growth. These systems are continuously subjected to a variety of stressors, such as aging materials, harsh environmental conditions, natural disasters, and increasing usage demands due to population growth and urbanization. As a result, the structural integrity and performance of such infrastructure are constantly challenged, making regular inspection, monitoring, and condition assessment imperative to ensure functionality, safety, and longevity [2].

In recent years, the growing emphasis on sustainability and resilience in infrastructure systems has amplified the need for more efficient and reliable inspection methods [3]. Accurate and timely inspection data serve as the foundation for effective decision-making in infrastructure management [4]. Such data enable authorities to prioritize maintenance, allocate resources effectively, and mitigate potential risks before they escalate into catastrophic failures. Furthermore, proactive condition assessment helps extend the service life of infrastructure assets, minimizes life-cycle costs, and ensures public safety. However, traditional inspection approaches, which often rely on manual processes and visual assessments, suffer from numerous limitations. These include inefficiency, subjectivity, lack of real-time reporting, and poor integration with modern infrastructure management systems. As a result, there is an increasing demand for advanced tools and frameworks that can address these shortcomings while improving accuracy and efficiency [5].

The integration of advanced technologies into inspection systems has significantly transformed the landscape of infrastructure condition assessment [6]. Recent advances in mobile computing, nondestructive testing (NDT), remote sensing, and field data acquisition tools have revolutionized the capabilities of inspection processes. Technologies such as digital cameras, speech recognition, laser scanning, thermal imaging, and radio frequency identification (RFID) now enable inspectors to collect and analyze high-quality data with unprecedented speed and precision. Mobile computing devices, including smartphones, handheld tablets, and wearable computers, provide robust and portable platforms for executing on-site inspection tasks and processing data in real-time [7]. These tools facilitate better communication, enhance inspector productivity, and ensure timely data availability for decision-makers [8].

Despite these advancements, challenges persist in the development and deployment of inspection systems. Existing inspection frameworks are often designed in isolation, tailored to specific infrastructure types or tasks, and lack interoperability. Such systems are frequently resource-intensive to develop, making them costly and inefficient, especially when common functionalities across multiple domains could be shared. Moreover, scalability and reusability remain major hurdles, as most current solutions are not adaptable to evolving technologies or diverse inspection requirements [9]. The fragmented nature of current inspection technologies limits their widespread adoption and inhibits the seamless integration of field data with infrastructure management systems [10].

To address these challenges, there is a clear need for a generalized, modular, and scalable inspection framework that simplifies the development and implementation of inspection support systems across various domains. This paper introduces the Java-Based Inspection Framework (JIF), a comprehensive solution that leverages modern computing technologies and object-oriented design principles to streamline field inspection processes. JIF offers a reusable software architecture that encapsulates core components of inspection systems, including inspection tasks, data acquisition, analysis, and domain-specific knowledge. By abstracting and modularizing the repetitive elements common to most inspection workflows, JIF significantly reduces development time, enhances software reliability, and promotes the reuse of system components [11]. Furthermore, JIF provides flexibility for customization and scalability, allowing it to adapt to diverse inspection requirements across different types of infrastructure [12].

The Java-Based Inspection Framework not only addresses the current limitations of inspection systems but also paves the way for future advancements [13]. By integrating modern technologies and fostering collaboration across domains, JIF enables more efficient, cost-effective, and sustainable infrastructure management [14]. This framework serves as a foundation for developing next-generation inspection tools that are better equipped to meet the challenges of maintaining and rehabilitating critical infrastructure systems in an era of rapid technological progress and growing infrastructure demands [15].

The maintenance, repair, and rehabilitation of civil infrastructure systems are critical components of sustainable development and public safety [16]. Civil infrastructure, including bridges, highways, buildings, and utility networks, represents a backbone of economic and societal growth. These systems are continuously subjected to a variety of stressors, such as aging materials, harsh environmental conditions, natural disasters, and increasing usage demands due to population growth and urbanization. As a result, the structural integrity and performance of such infrastructure are constantly challenged, making regular inspection, monitoring, and condition assessment imperative to ensure functionality, safety, and longevity [17].

In recent years, the growing emphasis on sustainability and resilience in infrastructure systems has amplified the need for more efficient and reliable inspection methods. Accurate and timely inspection data serve as the foundation for effective decision-making in infrastructure management [18]. Such data enable authorities to prioritize maintenance, allocate resources effectively, and mitigate potential risks before they escalate into catastrophic failures. Furthermore, proactive condition assessment helps extend the service life of infrastructure assets, minimizes life-cycle costs, and ensures public safety. However, traditional inspection approaches, which often rely on manual processes and visual assessments, suffer from numerous limitations [19]. These include inefficiency, subjectivity, lack of real-time reporting, and poor integration with modern infrastructure management systems. As a result, there is an increasing demand for advanced tools and frameworks that can address these shortcomings while improving accuracy and efficiency [20].

The dynamic nature of infrastructure inspections poses unique challenges. Inspectors must operate in diverse and often hazardous environments, ranging from bridge decks and tunnels to high-rise buildings and underground facilities. Field inspections require not only careful observation but also real-time access to historical data, manuals, and engineering drawings. Simultaneously, inspectors must efficiently collect and process new data, such as visual observations, measurements, photographs, and sensor outputs. The inspection results must then be seamlessly integrated into existing systems, such as Bridge Management Systems (BMS) and decision-support tools like the National Bridge Inventory (NBI), to ensure effective decision-making and maintenance planning.

Traditional inspection methods, which rely heavily on paper-based processes, exacerbate these challenges. Inspectors often face difficulties synchronizing current field observations with historical records, leading to delays, errors, and incomplete assessments. Paper-based forms, such as PennDOT’s D-450 form for bridge inspection, are prone to inaccuracies and inconsistencies, while post-inspection data entry and analysis become time-consuming and labor-intensive. Although digital systems have begun to replace paper-based methods, many of these solutions are ad hoc, task-specific, and lack flexibility. Their inability to adapt to varying inspection domains limits scalability and hinders the creation of a universal inspection support system.

The emergence of mobile computing and advanced data collection technologies has significantly enhanced the capabilities of inspection systems. These technologies provide inspectors with the tools to collect, process, and analyze infrastructure data with improved accuracy and efficiency. Key advancements include:

Mobile Computing Devices: Wearable computers, rugged tablets, and handheld devices offer robust, portable platforms for data collection, storage, and real-time reporting. Devices such as Fujitsu LifeBook, IBM ThinkPad, and wearable systems from Xybernaut provide sufficient processing power and durability for on-site tasks, even in harsh environments.

Data Collection Tools: A range of advanced tools, including digital cameras, speech recognition systems, laser scanners, and barcode readers, allow inspectors to collect multimedia-rich, high-quality data in real-time. Among these, speech recognition systems are particularly advantageous in environments where manual input is impractical, enabling hands-free operation and faster data capture.

| Data Integration | Accuracy (%) | Efficiency Improvement (%) | Time Reduction (%) | Implementation Time |

| High (AI-BIM integration) | 93.4 | 40 | 35 | 6 months |

| Moderate (Human-robot systems) | 95.2 | 50 | 45 | 4 months |

| High (3D modeling, UAV integration) | 91.8 | 60 | 50 | 8 months |

| Low (Manual validation required) | 92.7 | 30 | 40 | 5 months |

| High (InSAR-GIS interoperability) | 89.5 | 35 | 30 | 7 months |

| High (3D-BIM integration) | 94.1 | 45 | 35 | 6 months |

| Moderate (Guideline-driven system) | 88.9 | 25 | 20 | 9 months |

Information Integration: Technologies that support XML-based data exchange formats facilitate seamless integration of inspection data with existing infrastructure management databases. This interoperability ensures that inspection results can be easily synchronized with systems like BMS or NBI, enabling informed decision-making and efficient resource allocation.

While these modern technologies have transformed inspection capabilities, the development and deployment of comprehensive inspection systems remain complex. Each inspection domain—whether it involves bridges, tunnels, or buildings—has unique workflows, tools, and data requirements. As a result, designing a universal and scalable solution that addresses the needs of diverse inspection contexts remains a significant challenge.

To overcome these limitations, there is a pressing need for a modular, reusable, and scalable framework that simplifies the development of Field Inspection Support Systems (FISS) across various infrastructure domains. This paper introduces the Java-Based Inspection Framework (JIF), a comprehensive solution that leverages modern computing technologies and object-oriented design principles to streamline field inspection processes. JIF offers a reusable software architecture that encapsulates core components of inspection systems, including inspection tasks, data acquisition, analysis, and domain-specific knowledge. By abstracting and modularizing the repetitive elements common to most inspection workflows, JIF significantly reduces development time, enhances software reliability, and promotes the reuse of system components.

The Java-Based Inspection Framework not only addresses the current limitations of inspection systems but also paves the way for future advancements. By integrating modern technologies and fostering collaboration across domains, JIF enables more efficient, cost-effective, and sustainable infrastructure management. This framework serves as a foundation for developing next-generation inspection tools that are better equipped to meet the challenges of maintaining and rehabilitating critical infrastructure systems in an era of rapid technological progress and growing infrastructure demands.

The maintenance, repair, and rehabilitation of civil infrastructure systems are critical components of sustainable development and public safety. Civil infrastructure, including bridges, highways, buildings, and utility networks, represents a backbone of economic and societal growth. These systems are continuously subjected to a variety of stressors, such as aging materials, harsh environmental conditions, natural disasters, and increasing usage demands due to population growth and urbanization. As a result, the structural integrity and performance of such infrastructure are constantly challenged, making regular inspection, monitoring, and condition assessment imperative to ensure functionality, safety, and longevity.

In recent years, the growing emphasis on sustainability and resilience in infrastructure systems has amplified the need for more efficient and reliable inspection methods. Accurate and timely inspection data serve as the foundation for effective decision-making in infrastructure management. Such data enable authorities to prioritize maintenance, allocate resources effectively, and mitigate potential risks before they escalate into catastrophic failures. Furthermore, proactive condition assessment helps extend the service life of infrastructure assets, minimizes life-cycle costs, and ensures public safety. However, traditional inspection approaches, which often rely on manual processes and visual assessments, suffer from numerous limitations. These include inefficiency, subjectivity, lack of real-time reporting, and poor integration with modern infrastructure management systems. As a result, there is an increasing demand for advanced tools and frameworks that can address these shortcomings while improving accuracy and efficiency.

The dynamic nature of infrastructure inspections poses unique challenges. Inspectors must operate in diverse and often hazardous environments, ranging from bridge decks and tunnels to high-rise buildings and underground facilities. Field inspections require not only careful observation but also real-time access to historical data, manuals, and engineering drawings. Simultaneously, inspectors must efficiently collect and process new data, such as visual observations, measurements, photographs, and sensor outputs. The inspection results must then be seamlessly integrated into existing systems, such as Bridge Management Systems (BMS) and decision-support tools like the National Bridge Inventory (NBI), to ensure effective decision-making and maintenance planning.

Traditional inspection methods, which rely heavily on paper-based processes, exacerbate these challenges. Inspectors often face difficulties synchronizing current field observations with historical records, leading to delays, errors, and incomplete assessments. Paper-based forms, such as PennDOT’s D-450 form for bridge inspection, are prone to inaccuracies and inconsistencies, while post-inspection data entry and analysis become time-consuming and labor-intensive. Although digital systems have begun to replace paper-based methods, many of these solutions are ad hoc, task-specific, and lack flexibility. Their inability to adapt to varying inspection domains limits scalability and hinders the creation of a universal inspection support system.

The emergence of mobile computing and advanced data collection technologies has significantly enhanced the capabilities of inspection systems. These technologies provide inspectors with the tools to collect, process, and analyze infrastructure data with improved accuracy and efficiency. Key advancements include:

Mobile Computing Devices: Wearable computers, rugged tablets, and handheld devices offer robust, portable platforms for data collection, storage, and real-time reporting. Devices such as Fujitsu LifeBook, IBM ThinkPad, and wearable systems from Xybernaut provide sufficient processing power and durability for on-site tasks, even in harsh environments.

Data Collection Tools: A range of advanced tools, including digital cameras, speech recognition systems, laser scanners, and barcode readers, allow inspectors to collect multimedia-rich, high-quality data in real-time. Among these, speech recognition systems are particularly advantageous in environments where manual input is impractical, enabling hands-free operation and faster data capture.

Information Integration: Technologies that support XML-based data exchange formats facilitate seamless integration of inspection data with existing infrastructure management databases. This interoperability ensures that inspection results can be easily synchronized with systems like BMS or NBI, enabling informed decision-making and efficient resource allocation.

While these modern technologies have transformed inspection capabilities, the development and deployment of comprehensive inspection systems remain complex. Each inspection domain—whether it involves bridges, tunnels, or buildings—has unique workflows, tools, and data requirements. As a result, designing a universal and scalable solution that addresses the needs of diverse inspection contexts remains a significant challenge.

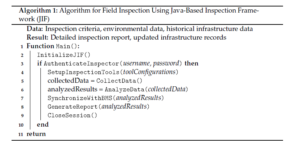

The Java-Based Inspection Framework (JIF) proposed in this paper provides a robust solution to the challenges associated with developing Field Inspection Support Systems (FISS). JIF is a modular, customizable software environment that captures the common elements shared across various inspection domains. By leveraging the object-oriented capabilities of Java, JIF enables developers to streamline the creation of inspection systems through a reusable and extensible architecture. This approach significantly reduces system development complexities and costs while enhancing scalability, maintainability, and overall performance.

Reuse Common Components: JIF allows developers to reuse core elements such as data collection tools, task workflows, and inspection knowledge across different inspection activities. By identifying and abstracting repetitive elements common to most workflows, JIF eliminates redundant development efforts and ensures consistency across systems.

Reduce Development Time: JIF provides a pre-structured architecture that simplifies the development process. Developers can focus on customization and domain-specific requirements rather than building systems from scratch. This results in faster implementation and reduced time-to-market for inspection solutions.

Enhance System Reliability: The modular design of JIF promotes better system maintainability, adaptability, and reliability. Errors and inconsistencies are minimized through the systematic organization of components, leading to robust and stable systems.

The JIF architecture operates at three primary layers, ensuring a clear and organized approach to system development:

Inspection Domain Objects: This layer represents core entities involved in inspections, such as inspection elements (e.g., bridge components, structural joints) and inspection data (e.g., measurements, photographs, sensor readings). By encapsulating domain-specific elements, this layer provides a foundation for accurate and consistent data representation.

Tasks: The task layer defines key inspection activities, including data collection, analysis, and reporting. Workflows are modularized to allow flexibility and scalability, enabling the system to accommodate evolving requirements and domain-specific processes.

Application Layer: This layer serves as the user interface and the overall control hub of the inspection system. It integrates the components of the other layers, providing inspectors and developers with an intuitive and user-friendly interface for performing inspection tasks and managing data.

JIF further simplifies development by supporting XML-based scripting to encode domain-specific knowledge, inspection elements, and task workflows. This feature eliminates the need for extensive coding, allowing developers to customize inspection processes quickly and efficiently. XML-based customization ensures adaptability across different inspection domains and accelerates system deployment.

By separating the inspection workflow into well-defined layers and providing reusable components, JIF promotes a modular, scalable, and cost-effective approach to developing Field Inspection Support Systems. The framework addresses the limitations of existing ad hoc solutions, offering a robust foundation for advanced inspection tools that can adapt to diverse infrastructure challenges.

To overcome these limitations, there is a pressing need for a modular, reusable, and scalable framework that simplifies the development of Field Inspection Support Systems (FISS) across various infrastructure domains. This paper introduces the Java-Based Inspection Framework (JIF), a comprehensive solution that leverages modern computing technologies and object-oriented design principles to streamline field inspection processes. JIF offers a reusable software architecture that encapsulates core components of inspection systems, including inspection tasks, data acquisition, analysis, and domain-specific knowledge. By abstracting and modularizing the repetitive elements common to most inspection workflows, JIF significantly reduces development time, enhances software reliability, and promotes the reuse of system components.

The Java-Based Inspection Framework not only addresses the current limitations of inspection systems but also paves the way for future advancements. By integrating modern technologies and fostering collaboration across domains, JIF enables more efficient, cost-effective, and sustainable infrastructure management. This framework serves as a foundation for developing next-generation inspection tools that are better equipped to meet the challenges of maintaining and rehabilitating critical infrastructure systems in an era of rapid technological progress and growing infrastructure demands.

This paper presented the Java-Based Inspection Framework (JIF) as a modular and reusable solution to address the challenges in developing field inspection support systems for civil infrastructure. By capturing common components of inspection processes, JIF streamlines system development, reduces costs, and improves reliability. The framework’s object-oriented design allows for the separation of key inspection elements, tasks, and knowledge, facilitating flexibility and customization across various inspection activities.

In conclusion, JIF provides a scalable, reusable, and efficient framework for developing field inspection support systems. It bridges the gap between modern computing technologies and practical field inspection requirements, enabling the creation of reliable systems that can enhance data collection, analysis, and decision-making processes in civil infrastructure management. As infrastructure inspection continues to evolve, frameworks like JIF will play a critical role in promoting innovation and efficiency across the industry.

Frangopol, D. M., & Liu, M. (2019). Maintenance and management of civil infrastructure based on condition, safety, optimization, and life-cycle cost. Structures and infrastructure systems, 96-108.

Agdas, D., Rice, J. A., Martinez, J. R., & Lasa, I. R. (2016). Comparison of visual inspection and structural-health monitoring as bridge condition assessment methods. Journal of Performance of Constructed Facilities, 30(3), 04015049.

Achillopoulou, D. V., Mitoulis, S. A., Argyroudis, S. A., & Wang, Y. (2020). Monitoring of transport infrastructure exposed to multiple hazards: A roadmap for building resilience. Science of the total environment, 746, 141001.

Wu, C., Wu, P., Wang, J., Jiang, R., Chen, M., & Wang, X. (2021). Critical review of data-driven decision-making in bridge operation and maintenance. Structure and infrastructure engineering, 18(1), 47-70.

Latif, S., Driss, M., Boulila, W., Huma, Z. E., Jamal, S. S., Idrees, Z., & Ahmad, J. (2021). Deep learning for the industrial internet of things (iiot): A comprehensive survey of techniques, implementation frameworks, potential applications, and future directions. Sensors, 21(22), 7518.

Taheri, A., & Sobanjo, J. (2024). Civil Integrated Management (CIM) for Advanced Level Applications to Transportation Infrastructure: A State-of-the-Art Review. Infrastructures, 9(6), 90.

Horak, K. E., DeLand, S. M., & Blair, D. S. (2014). The feasibility of mobile computing for on-site inspection (No. SAND2014-18291). Sandia National Lab.(SNL-NM), Albuquerque, NM (United States).

Swanson, R. (2007). Analysis for improving performance: Tools for diagnosing organizations and documenting workplace expertise. Berrett-Koehler Publishers.

Javed, A. R., Shahzad, F., ur Rehman, S., Zikria, Y. B., Razzak, I., Jalil, Z., & Xu, G. (2022). Future smart cities: Requirements, emerging technologies, applications, challenges, and future aspects. Cities, 129, 103794.

Omrany, H., Al-Obaidi, K. M., Husain, A., & Ghaffarianhoseini, A. (2023). Digital twins in the construction industry: a comprehensive review of current implementations, enabling technologies, and future directions. Sustainability, 15(14), 10908.

Stier, S. P., Kreisbeck, C., Ihssen, H., Popp, M. A., Hauch, J., Malek, K., … & Kozdras, M. (2024). Materials Acceleration Platforms (MAPs): Accelerating Materials Research and Development to Meet Urgent Societal Challenges. Advanced Materials, 36(45), 2407791.

Sikeridis, D., Papapanagiotou, I., Rimal, B. P., & Devetsikiotis, M. (2017). A Comparative taxonomy and survey of public cloud infrastructure vendors. arXiv preprint arXiv:1710.01476.

Paronen, T. (2015). A web-based monitoring system for the Industrial Internet (Master’s thesis).

Sahu, S., Kaur, A., Singh, G., & Arya, S. K. (2023). Harnessing the potential of microalgae-bacteria interaction for eco-friendly wastewater treatment: a review on new strategies involving machine learning and artificial intelligence. Journal of Environmental Management, 346, 119004.

Reda Taha, M., Ayyub, B. M., Soga, K., Daghash, S., Heras Murcia, D., Moreu, F., & Soliman, E. (2021). Emerging technologies for resilient infrastructure: Conspectus and roadmap. ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems, Part A: Civil Engineering, 7(2), 03121002.

Frangopol, D. M., & Liu, M. (2019). Maintenance and management of civil infrastructure based on condition, safety, optimization, and life-cycle cost. Structures and infrastructure systems, 96-108.

Agdas, D., Rice, J. A., Martinez, J. R., & Lasa, I. R. (2016). Comparison of visual inspection and structural-health monitoring as bridge condition assessment methods. Journal of Performance of Constructed Facilities, 30(3), 04015049.

Wu, C., Wu, P., Wang, J., Jiang, R., Chen, M., & Wang, X. (2021). Critical review of data-driven decision-making in bridge operation and maintenance. Structure and infrastructure engineering, 18(1), 47-70.

Newman, T. S., & Jain, A. K. (1995). A survey of automated visual inspection. Computer vision and image understanding, 61(2), 231-262.

Latif, S., Driss, M., Boulila, W., Huma, Z. E., Jamal, S. S., Idrees, Z., & Ahmad, J. (2021). Deep learning for the industrial internet of things (iiot): A comprehensive survey of techniques, implementation frameworks, potential applications, and future directions. Sensors, 21(22), 7518.