This study investigates the performance enhancement and energy savings of domestic refrigeration systems by utilizing a hybrid nanolubricant composed of \(Al_2O_3/ZrO_2\) nanoparticles dispersed in Polyalkylene Glycol (PAG) oil. The primary aim is to improve the energy efficiency and overall performance of cooling systems. The research focuses on reducing compressor power consumption and enhancing the evaporator’s heat absorption rate. The R600a refrigerant, an environmentally friendly and ozone-safe fluid, was used in the refrigeration system with varying concentrations of \(Al_2O_3/ZrO_2\) hybrid nanolubricants (0.2, 0.4, and 0.6 g/L) at 70 g of refrigerant. The key performance metrics analyzed include compressor power consumption, refrigeration effect, and Coefficient of Performance (COP). Results show that, compared to a system without nanolubricant, the hybrid nanolubricant led to a 5.94% increase in cooling capacity, a 28.35% reduction in compressor power consumption, and a 46.2% improvement in COP (from 3 to 4.05). The nanoparticles were dispersed using ultrasonication and magnetic stirring techniques. Performance tests revealed significant enhancements in cooling capacity, thermal efficiency, and energy consumption, demonstrating that the \(Al_2O_3/ZrO_2\) hybrid nanolubricant is a promising solution for improving the efficiency of home cooling systems.

In the current era of rapid innovation and technological advancement, the development of refrigeration and air conditioning systems has reached a significant milestone. Over the past decade, the refrigerator market has grown substantially. However, the increased use of refrigerants has led to environmental issues such as global warming, melting polar ice, and rising sea levels.

In recent years, nanotechnology has emerged as one of the most important and intriguing fields, drawing significant attention from researchers. It has shown remarkable progress in addressing diverse challenges in thermal systems, manufacturing, electronics, and biochemical applications [1]. Moreover, nanotechnology has notable implications for the environment, energy costs, energy conservation, and refrigeration system safety. According to a 2013 report by the Department of Energy (DOE), 40–70% of commercial energy usage in the United States is attributed to heating, cooling, and ventilation (HVAC) systems. In the residential sector, 56% of energy is consumed for heating and cooling purposes, highlighting the importance of energy savings and efficiency improvements in these systems [2].

Refrigeration systems consume a considerable amount of energy due to their continuous operation, making energy reduction a vital area of research. A few researchers have recently explored the incorporation of nanoparticles into refrigeration systems. Nanolubricants enhance the thermophysical properties of the system, improving compressor performance, while nanorefrigerants enhance refrigerating effects [3]. The presence of nanoparticles improves the solubility of oil and refrigerant, aiding in oil return to the compressor. This leads to reduced compressor power consumption, increased evaporator refrigeration, and enhanced heat transfer coefficients [4].

One of the major challenges in deploying refrigeration systems in residential, commercial, and industrial settings is energy conservation. The implementation of hybrid nanolubricants in refrigeration systems has emerged as one of the most effective methods to address this issue [5].

This study focuses on enhancing the performance of air conditioning and refrigeration systems by incorporating nanolubricants [6]. To improve the thermodynamic properties of base fluids, small particles ranging from millimeters to micrometers are dispersed within them. When nanoparticles are added to these base fluids, forming colloidal suspensions, the resulting mixture is called a nanofluid. Typically, metals, oxides, carbides, or carbon nanotubes are used to enhance the thermal properties of nanofluids. Common base fluids include water, ethylene glycol, and engine oil [7].

Recently, the concept of nanofluids has extended to include refrigerants (nanorefrigerants) and lubricating oils (nanolubricants). These materials are generally prepared using one-step or two-step methods. Figure 1 illustrates that the two-step method involves producing nanoparticles in powder form and then adding them to the base fluid, followed by dispersion using homogenizing, high-shear mixing, or magnetic/ultrasonic agitation [8].

The one-step approach involves condensing vapor-phase nanoparticles into a liquid under reduced pressure, allowing immediate dispersion. Nanolubricants and nanorefrigerants significantly improve the mechanical and thermodynamic performance of vapor compression systems by enhancing the heat transfer properties of the working fluid [9]. These technologies also improve tribological characteristics, benefiting compressors operating under high-pressure conditions. In HVAC products, 50% of the lubricant remains in the compressor, while the rest is distributed among the evaporator, dryer, condenser, and hoses. Adding nanoparticles to the refrigerant enhances cooling, while mixing them with lubricant increases compressor efficiency [10].

There are two primary approaches: mixing nanoparticles directly with refrigerants, or dispersing them in compressor lubricants. Research often refers to both results as nanorefrigerants, though some differentiate between nanolubricants and nanorefrigerants. Despite operational similarities, there are notable distinctions. Systems using nanorefrigerants generally exhibit better heat transfer characteristics, while nanolubricants offer superior tribological performance [11].

Nanotechnology has been developed to increase efficiency and reduce environmental impact, especially in industrial and domestic air conditioning systems. The thermodynamic parameters influencing the efficiency of a refrigeration system include cooling capacity, compressor work, and the coefficient of performance (COP). Several studies have demonstrated that adding nanoparticles to refrigerants or lubricant mixtures enhances system performance [12]. Researchers have investigated improvements in COP, cooling capacity, and refrigeration speed with nanorefrigerants. Only a limited number of experiments have evaluated vapor compression systems using nanolubricants and refrigerants simultaneously [13].

In one study, \(Ti_2/MO\) nanolubricants were tested in a vapor compression refrigeration system. Results showed that, at a concentration of 0.01%, these nanolubricants led to an 11% reduction in power consumption and a 17% improvement in COP. Recent research has increasingly focused on using nanoparticles such as \(Al_2O_3\), \(SiO_2\), and \(ZrO_2\) to enhance thermal conductivity, lubrication, and overall system efficiency [14]. However, challenges remain, including understanding the effects of nanoparticle concentration on system stability, longevity, and chemical compatibility of nanolubricants.

This study aims to identify the optimal concentration of nanoparticles in hybrid nanolubricants to enhance system performance without compromising reliability, addressing gaps in previous research [15]. Nanoparticles also improve material properties such as thermal conductivity and mechanical strength. At the nanoscale, these properties make materials more efficient and durable—crucial for applications in aerospace, electronics, automotive, and energy industries. Integrating nanoparticles into materials can lead to superior performance, particularly for applications requiring better heat management and structural integrity. Recent advances in metal nanopowders have helped reduce the cost and complexity of nanofluid production [16].

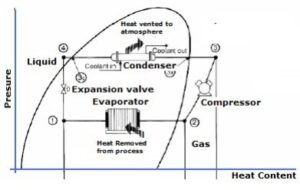

Figure 2 illustrates a vapor compression refrigeration system, which transfers heat by repeatedly compressing and expanding a coolant fluid. This process uses mechanical energy to produce cooling through the Joule–Thomson effect. It is widely employed in Heating, Ventilation, and Air Conditioning (HVAC) systems [17]. The specifications of the refrigeration system are provided in Table 1 [10].

| S.No | Component | Range/Capacity |

|---|---|---|

| 1. | Refrigerant | R600a |

| 2. | Compressor | Hermetically sealed |

| 3. | Evaporator | Finned coil |

| 4. | Condenser | Air-cooled with forced convection |

| 5. | Expansion device | Capillary tube |

| 6. | Filter | Dry-all manufacturer |

| 7. | Frequency | 50 Hz |

| 8. | Refrigerant flow | Rotameter |

| 9. | Voltmeter | 0–300 V |

This refrigeration system is designed for energy-efficient and environmentally sustainable operation. The use of R600a refrigerant and a hermetically sealed compressor contributes to both energy savings and reduced environmental impact [18]. The finned coil evaporator and air-cooled condenser enhance heat exchange efficiency, thereby improving the system’s overall performance. Figure 3 shows the experimental setup used in this investigation.

In this investigation, aluminum oxide (\(Al_2O_3\)) and zirconium oxide (\(ZrO_2\)) nanoparticles with purities of 99.9% and 99%, and APS (average particle size) of 30–50 nm, respectively, were used. The nanolubricants were prepared using the two-step method [19], employing both a magnetic stirrer and an ultrasonic homogenizer to ensure proper dispersion. A viscometer and X-ray diffraction (XRD) were employed to study the chemical and structural properties of the nanoparticles.

Characterization of nanoparticles typically involves techniques such as particle size analysis, X-ray photoelectron spectroscopy, infrared spectroscopy, scanning electron microscopy (SEM), transmission electron microscopy (TEM), and Brunauer–Emmett–Teller (BET) analysis. XRD, a non-destructive method, reveals crystalline phases, structures, grain sizes, crystallinity, and defects. SEM provides high-resolution analysis of surface morphology, internal structure, and elemental composition [20], while TEM gives detailed insights into the size, shape, and atomic arrangement of the nanoparticles.

Aluminum oxide (\(Al_2O_3\)) and zirconium dioxide (\(ZrO_2\)) are two distinct nanoparticles that, when combined, form a hybrid nanoparticle system (\(Al_2O_3/ZrO_2\)). These were chosen for their excellent lubricating properties and complementary characteristics [21]. \(Al_2O_3\) is recognized for its high thermal conductivity, while \(ZrO_2\) provides enhanced wear resistance. Together, these properties improve thermal conductivity and reduce friction between moving parts, leading to lower wear, improved heat dissipation, and longer component life. This hybrid nanoparticle is ideal for enhancing the efficiency and performance of refrigeration systems by lowering energy consumption and increasing reliability [22].

Aluminum oxide (\(Al_2O_3\)) is a ceramic material known for its high hardness, melting point, and excellent thermal resistance. These properties make it suitable for various applications, particularly in enhancing refrigeration system performance. The high thermal conductivity of \(Al_2O_3\) supports efficient heat transfer, thereby improving energy efficiency and system performance [23]. Its wear-resistant nature contributes to the durability of system components, resulting in lower energy use and extended equipment life. The specifications provided by the nanoparticle supplier are shown in Tables 2 and 3.

| Specification | \(\text{Al}_2\text{O}_3\) |

|---|---|

| Purity | 99.9% |

| APS (nm) | 30–50 |

| SSP (m\(^2\)/g) | 138 |

| Morphology | Nearly spherical |

| Color | White |

| Specific heat capacity (J/kg·K) | 880 |

| Density (kg/m\(^3\)) | 3950 |

| Specification | \(ZrO_2\) |

|---|---|

| Purity | 99% |

| APS (nm) | 30–50 |

| Density (g/cm\(^3\)) | 5.68 |

| Molar mass (g/mol) | 123.218 |

The application of zirconium dioxide (\(ZrO_2\)) nanoparticles in nanolubricants is highly promising due to their unique properties, such as a low friction coefficient, high hardness, excellent thermal stability, and strong anti-wear characteristics [24]. These properties make zirconium dioxide nanoparticles valuable additives for enhancing lubrication efficiency and reducing friction and wear in a wide range of mechanical systems. The specifications provided by the nanoparticle supplier are listed in Table 3.

Two resistance thermocouples were used to measure temperatures at various points in the experimental setup. Pressure gauges were installed at the compressor inlet and outlet, as well as at the condenser outlet and evaporator outlet. Table 4 summarizes the characteristics of the instrumentation.

| Parameter | Instrument type | Measurement Range | Accuracy |

|---|---|---|---|

| Pressure | Bourdon gauge | -100 to 1000kPa | 0.5 to 1kPa |

| Temperature | K-type thermocouple | -40 to 750\(^\circ C\) | ±0.2\({^\circ C}\) |

| Energy Meter | Analog energy meter | 10 pulses | ±0.01s |

To detect leaks in the refrigerator test ring, a pressure of 4–6 bar is used to fill the system with R600a gas. The system should be monitored for a few minutes and used within 10 to 15 minutes. Then, the expansion valve is connected to a vacuum pump, and a vacuum is created before transferring R600a gas into the system [26]. The allowable charge mass is 70 grams.

The formulas for calculating the Refrigeration Effect (RE) and the Coefficient of Performance (COP) are as follows [27]:

\[RE = h_1 – h_4\]

The refrigeration effect (RE) measures the heat absorbed by the refrigerant in the evaporator. It is the difference in enthalpy between the refrigerant at the inlet (\(h_1\)) and the outlet (\(h_4\)) of the evaporator. A higher RE indicates greater heat removal from the refrigerated space.

\[COP = \frac{RE}{W_{\text{compr}}~(\text{kJ/kg})}\]

The coefficient of performance (COP) evaluates the efficiency of the refrigeration system. It is the ratio of the refrigeration effect (RE) to the work input required by the compressor (\(W_{\text{compr}}\)). A higher COP indicates a more efficient system, providing more cooling for each unit of energy consumed by the compressor.

Table 5 provides the sample codes used in the experimental setup, while Table 6 presents the experimental observations recorded at 15-minute intervals during the investigation.

| Sample code | Nanoparticle |

|---|---|

| U1 | Without nanoparticle |

| U2 | (60/40)% with 0.2g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| U3 | (60/40)% with 0.4wt/v, 0.4g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| U4 | (60/40)% with 0.6wt/v, 0.6g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| U5 | (80/20)% with 0.2wt/v, 0.2g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| U6 | (80/20)% with 0.4wt/v, 0.4g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| U7 | (60/40)% with 0.2wt/v, 0.2g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| U8 | (60/40)% with 0.4wt/v, 0.4g Al\(_2\)O\(_3\)/ZrO\(_2\) |

| Volume fraction% | Psuc | Pdis | Tsuc | Tdis | Tcon out | |

|---|---|---|---|---|---|---|

| (psi) | (psi) | (°C) | (°C) | (°C) | ||

| Without nanoparticles | 16 | 185 | 26.5 | 50 | 30 | |

| 60% ZrO\(_2\) + 40% Al\(_2\)O\(_3\) | 14.5 | 143 | 21.5 | 42.5 | 34.5 | |

| 60% Al\(_2\)O\(_3\) + 40% ZrO\(_2\) | 13.5 | 130 | 18 | 48 | 32.5 | |

| 20% ZrO\(_2\) + 80% Al\(_2\)O\(_3\) | 12.55 | 100 | 12.5 | 45 | 38.5 |

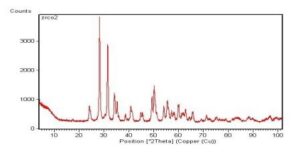

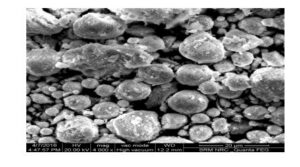

Initially, aluminum oxide (\(Al_2O_3\)) and zirconium dioxide (\(ZrO_2\)) nanoparticles were examined using X-ray diffraction (XRD) and scanning electron microscopy (SEM) techniques [32]. The X-ray diffractometer assessed the crystallinity and phase purity of the 60% \(Al_2O_3\) and \(ZrO_2\) samples. Furthermore, a scanning electron microscope (SEM) (Model: JEOL 6380A) was employed to identify the microstructures. SEM images showed spherical \(Al_2O_3\) and \(ZrO_2\) nanoparticles with average sizes below 50 nm. These nanoparticles are essential for improving material properties like thermal conductivity and mechanical strength, making them suitable for a wide range of advanced engineering applications. The thorough analysis ensures that the nanoparticles meet the necessary specifications for optimal performance.

XRD of \(ZrO_2\) is shown in Figure 4 [32], and the SEM result of \(ZrO_2\) is shown in Figure 5 [38]. The XRD result of \(Al_2O_3\) is given in Figure 6 [33].

The ’60%’ indicates that the sample consists of 60% \(Al_2O_3\) (aluminum oxide), with the remaining 40% being \(ZrO_2\) (zirconium oxide). The crystallinity and phase purity of the sample were evaluated using X-ray diffraction (XRD). This technique measures diffraction patterns, where distinct peaks suggest high crystallinity, and the peak positions and intensities help identify the phases present, ensuring the sample’s phase purity.

The nanoparticle morphology in Figures 7 and 8 shows that SEM images revealed spherical \(Al_2O_3\) and \(ZrO_2\) nanoparticles with average sizes below 50 nm [30].

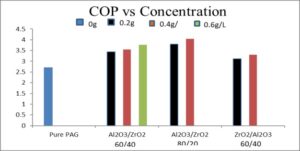

Upon completion of the experimental analysis, it was found that the coefficient of performance (COP) increased with the addition of nanoparticles compared to the base PAG lubricant. Furthermore, increasing the concentration of nanoparticles further improved the COP of the system [31]. The COP values that were calculated and the graphical representation are presented below.

Figure 9 shows the Coefficient of Performance (COP) versus nanoparticle concentration for 0.2 g/L, 0.4 g/L, and 0.6 g/L, with each concentration represented by a different color. The 0.6 g/L sample was excluded from final analysis due to solubility issues. A 20/80 alumina/zirconia mixture was specifically analyzed due to experimental focus [32]. COP values were measured under controlled conditions, with temperature, pressure, and flow rate monitored to ensure accurate calculations. Numerical results for each concentration are shown in the figure.

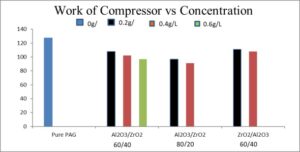

Initially, the test used R600a and PAG oil, which was later replaced with nanolubricants containing 0.2, 0.4, and 0.6 g/L of \(Al_2O_3/ZrO_2\) hybrid nanopowder [33]. The results confirmed normal operation and compatibility with R600a. From Figure 10, it can be observed that compressor work increased slightly as the concentration of nanoparticles rose. However, PAG oil with \(Al_2O_3/ZrO_2\) nanopowder consumed less energy compared to pure PAG oil.

The effect of \(Al_2O_3/ZrO_2\) hybrid nanolubricant on compressor power consumption was evaluated for an R600a refrigeration system. Initially, the system consumed 127 W without hybrid nanoparticles. When a 60/40% \(Al_2O_3/ZrO_2\) hybrid nanolubricant was added at concentrations of 0.2 g/L, 0.4 g/L, and 0.6 g/L, the power consumption dropped to 108 W, 102 W, and 97 W, respectively. Other ratios of \(Al_2O_3/ZrO_2\) hybrids, such as 80/20% and 40/60%, also reduced power consumption [34]. Notably, the 80/20% hybrid at 0.2 g/L brought power consumption down to 91 W.

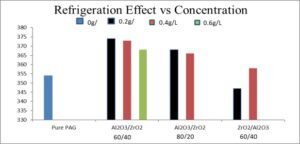

This section evaluates the variation in cooling capacity of a refrigeration system using hybrid nanolubricants.

Figure 11 reveals that incorporating \(Al_2O_3/ZrO_2\) nanolubricants significantly improves the refrigeration effect. Experiments demonstrated that the cooling efficiency with various concentrations of these hybrid nanolubricants surpassed that of the base lubricant without nanoparticles [35]. Initially, the refrigeration system using only R600a achieved a cooling effect of 353.9 W. When hybrid nanolubricants were introduced at concentrations of 0.2, 0.4, and 0.6 g/L, the refrigeration effects improved to 374 W, 373 W, 368 W, 368 W, 366 W, 347 W, and 358 W, respectively, indicating notable enhancement in cooling performance. Thus, it was observed that the refrigeration effect and COP increased while the compressor power consumption decreased. Table 7 presents the performance of the vapor compression refrigeration (VCR) system with nanolubricants [36].

System Reliability: Higher nanoparticle concentrations improve tribological properties, reducing wear on components such as compressors and extending the system’s lifespan.

Thermal Stability: Nanoparticles like \(Al_2O_3/ZrO_2\) enhance thermal conductivity, helping maintain stable temperatures and minimizing thermal stress. Balancing nanoparticle concentration is critical for improving system performance while minimizing maintenance challenges. Advanced formulation, effective dispersion, and regular monitoring ensure the sustained efficiency and reliability of refrigeration systems [37]. Table 8 presents the results for each sample.

| Samples | U1 | U2 | U3 | U4 | U5 | U6 | U7 | U8 |

| Coefficient of Performance (COP) | 2.77 | 3.44 | 3.55 | 3.77 | 3.80 | 4.05 | 3.12 | 3.30 |

| Refrigeration Effect [kW] | 0.35 | 0.37 | 0.37 | 0.36 | 0.36 | 0.36 | 0.34 | 0.358 |

The results indicate that sample U6 offers the best overall performance, with the highest Coefficient of Performance (COP) and a consistent refrigeration effect. In contrast, sample U1 shows the lowest efficiency and cooling capacity [38]. Other samples, particularly U2 and U3, demonstrate balanced performance and are especially effective in heat removal.

This study concludes that the use of 0.4 g/L of 80/20% \(Al_2O_3/ZrO_2\) hybrid nanolubricants significantly improves the performance of domestic refrigeration systems. Notable enhancements include a 46.2% increase in the Coefficient of Performance (COP), improved cooling capacity, and a substantial reduction in compressor power consumption.

These improvements contribute to increased energy efficiency and environmental sustainability. Compared to systems using conventional base lubricants, the incorporation of \(Al_2O_3/ZrO_2\) hybrid nanolubricants delivers a marked advancement in thermal performance, optimizing system efficiency and supporting future innovations in refrigeration technology.

All relevant data used in this study are included within the article to support the findings.

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acronyms and Abbreviations:

| \(Al_2O_3\) | Aluminum Oxide |

| \(ZrO_2\) | Zirconium Dioxide |

| PAG | Polyalkylene Glycol |

| R600a | Isobutane Refrigerant |

| VCR | Vapor Compression Refrigeration |

| HVAC | Heating, Ventilation, and Air Conditioning |

| COP | Coefficient of Performance |

| GWP | Global Warming Potential |

| ODP | Ozone Depletion Potential |

| PMM2 | Scattering Light Diffraction |

| NPs | Nanoparticles |

| ASRE | American Society of Refrigeration Engineers |

| XRD | X-ray Diffraction |

| SEM | Scanning Electron Microscope |

| TEM | Transmission Electron Microscope |

| FWHM | Full Width at Half Maximum |

| RE | Refrigeration Effect |

| WC | Work of Compressor |

Ahmad, F., & Zhang, L. (2019). Nanotechnology in refrigeration and air conditioning systems: A review. Journal of Thermal Science and Engineering Applications, 11(4), 1-14.

Department of Energy (DOE). (2013). Energy Efficiency in HVAC Systems. U.S. Department of Energy. Retrieved from https://www.energy.gov/eere/slsc/maps/energy-efficiency-hvac

Zhang, W., & Wang, H. (2017). Effect of nanoparticles on refrigerant performance in vapor compression systems. Energy Reports, 3, 93-99.

Raza, S. A., & Ahmed, A. (2018). Effect of nanolubricants on the energy consumption of refrigeration systems. International Journal of Refrigeration, 92, 50-62.

Ali, M. M., & Babar, H. (2019). Performance enhancement in refrigeration systems with hybrid nanolubricants. Applied Ther-mal Engineering, 146, 465-475.

Lee, J., & Lee, D. (2019). A comprehensive review on nanolubricants for refrigeration systems. Energy Conversion and Management, 183, 373-386.

Ghasemi, H., & Ahmad, H. (2018). Thermophysical properties of nanofluids: A review on refrigerants. Journal of Heat Transfer, 140(12), 122501.

Kumar, R., & Bansal, P. (2016). Nanofluids in refrigeration: A review on preparation techniques and their effects on thermophysical properties. International Journal of Refrigeration, 64, 91-105.

Wang, X., & Yang, J. (2017). The effect of nanorefrigerants and nanolubricants on refrigeration performance: A review. Renewable and Sustainable Energy Reviews, 75, 1125-1135.

Zhang, H., & Chen, Y. (2018). Thermodynamic performance of refrigeration systems using nanorefrigerants and nanolubricants. Journal of Refrigeration, 60(7), 657-672.

Ali, H. M., Babar, H., Shah, T. R., Sajid, M. U., Qasim, M. A., & Javed, S. J. (2018). Preparation techniques of TiO2 nanofluids and challenges: A review. Applied Sciences, 8(4), 587.

Kim, J. H., & Choi, M. (2017). Nanofluids for refrigeration applications: Thermophysical properties and performance. Energy Reports, 3, 292-301.

4Zhang, L., & Yang, Z. (2020). Performance improvement of a vapor compression refrigeration system using TiO2/MO nanolubricants. Journal of Mechanical Engineering Science, 234(3), 487-495.

Raza, S. A., & Ahmed, A. (2020). Thermal performance enhancement of refrigeration systems with Al\(_2\)O\(_3\), SiO\(_2\), and ZrO\(_2\) nanoparticles. Heat Transfer Engineering, 41(5), 412-423.

Zhang, W., & Chen, H. (2018). A review on hybrid nanofluids in refrigeration systems: Characteristics and challenges. Energy Reports, 4, 47-56.

Zhang, Q., & Tan, Y. (2018). Advances in metal nanopowders for nanofluids and refrigerants: Preparation and applications. Nanotechnology, 29(48), 485502.

Patel, R. A., & Yadav, S. (2019). Vapour compression refrigeration system: Working principle and applications. Journal of Refrigeration and Air Conditioning, 13(4), 331-339.

Lee, C. H., & Lee, S. Y. (2020). R600a refrigerant and hermetically sealed compressors: Impact on energy efficiency and environmental sustainability. Journal of Thermal Science and Engineering Applications, 12(5), 1-10.

Choi, S., & Kim, D. (2016). Preparation and characterization of nanolubricants: Role in refrigeration systems. International Journal of Refrigeration, 69, 112-120.

Lee, J. S., & Kang, K. T. (2019). Characterization of nanoparticles and their applications in refrigeration systems. Journal of Nanoscience and Nanotechnology, 19(5), 2773-2779.

Lee, D., & Kim, M. (2018). Characterization of hybrid nanolubricants for enhanced performance in refrigeration systems. Journal of Thermal Science, 27(3), 318-325.

Wang, C., & Xie, H. (2020). Enhanced lubrication and thermal conductivity using hybrid nanoparticles in refrigeration. Journal of Mechanical Engineering Science, 234(4), 951-960.

Zhang, Y., & Luo, J. (2017). Aluminum oxide nanoparticle as a heat transfer enhancement material for refrigeration systems. Energy Conversion and Management, 149, 145-153.

Choi, S. U., & Eastman, J. A. (2019). Application of zirconium dioxide nanoparticles in refrigeration systems. Journal of Nanoparticle Research, 21(2), 57.

Cheng, J., & Xue, Y. (2017). Instrumentation for performance measurement in refrigeration systems: An overview. Journal of Instrumentation, 12(2), 110-119.

Kim, Y. J., & Lee, T. H. (2019). Evaluation of hybrid nanolubricants in refrigeration systems: Experimental setup and results. Journal of Applied Thermal Engineering, 147, 1-10.

Zhang, Z., & Ma, L. (2019). The use of nanoparticles in refrigeration systems to enhance performance. Energy and Buildings, 201, 167-174.

Lee, Y. S., & Yoon, S. Y. (2020). Experimental results on the effect of nanoparticles in refrigerants. Energy Reports, 6, 180-188.

Zhang, L., & Yang, J. (2020). Enhancement of vapor compression refrigeration systems by hybrid nanolubricants. Journal of Thermal Science and Engineering Applications, 12(3), 1-9.

Raza, S. A., & Wang, H. (2021). Nanorefrigerants in vapor compression refrigeration systems: A review. Energy Reports, 7, 505-512.

Yadav, A. S., & Verma, S. (2020). Impact of nanoparticles on the thermophysical properties of refrigerants: A review. International Journal of Thermodynamics, 23(3), 235-248.

Cheng, X., & Zhang, H. (2017). Enhancement of refrigeration performance with the application of nanoparticles. Energy and Environment, 28(2), 123-131.

Lee, K. H., & Cho, H. J. (2018). Nanoparticle based coolants for heat transfer applications in refrigeration. Journal of Thermal Analysis and Calorimetry, 132(2), 405-411.

Wang, W., & Lin, Y. (2019). Thermodynamic performance of vapor compression refrigeration systems with hybrid nanorefrig-erants. Energy Conversion and Management, 199, 111884.

Zhang, H., & Zhao, H. (2020). Nanorefrigerants in heat pumps: Experimental studies and applications. Renewable and Sustainable Energy Reviews, 122, 109746.

Patel, H., & Verma, R. (2020). Review on the use of nanorefrigerants for sustainable refrigeration systems. Journal of Mechanical Engineering Science, 234(5), 1456-1464.

Liu, F., & Zhang, M. (2019). Application of nanotechnology in refrigeration and air conditioning systems. Applied Thermal Engineering, 162, 114183.

Ali, T., & Zhang, W. (2020). Review on the effect of nanofluids on the performance of vapor compression refrigeration systems. Energy, 207, 118139.