This study investigates the low-cycle fatigue (LCF) behavior of nickel-based single-crystal superalloy DD3 at 620°C, considering both smooth and notched specimens. A novel LCF life model is proposed, incorporating the mean stress effect and based on crystallographic theory. The model describes LCF life as a power function of the maximum resolved shear stress of activated slip systems, with parameters obtainable from smooth round specimens at various stress levels. Validation of the model is demonstrated through excellent agreement with experimental results from additional smooth and notched round specimens, further supported by SEM analysis of fracture surfaces. The research also provides insight into the deformation mechanisms of nickel-based single-crystal superalloys under multiaxial stress states.

Nickel-based single-crystal superalloys have become the material of choice for gas turbine blades due to their exceptional creep, fracture, and fatigue properties, which surpass those of conventionally cast alloys. The absence of grain boundaries in single crystals is responsible for their superior high-temperature properties, but also leads to anisotropic mechanical properties. Turbine blades are subjected to complex multiaxial stress states due to their intricate shape, temperature gradients, and aerodynamic loading. This is particularly pronounced in the blade root region, where the blades connect to the turbine disc [1].

Understanding the low-cycle fatigue (LCF) behavior of nickel-based single-crystal superalloys at high temperatures is crucial for ensuring the reliability and performance of gas turbines. Previous studies have investigated the fatigue behavior of single-crystal superalloys, such as CMSX-2 and Rene N4, focusing on microcrack growth, defect size and location, and crack growth. Additionally, research has explored the influence of crystallographic orientations on fatigue-creep behavior [2].

Building on this existing knowledge, the present study aims to simulate the LCF behavior of blade roots using a set of notched specimens. By combining experimental results with finite element analysis, a novel LCF life model is proposed for multiaxial stress states. Furthermore, scanning electron microscopy (SEM) observations of fracture surfaces provide valuable insights into the deformation and damage micromechanisms of nickel-based single-crystal superalloys at high temperatures. This research contributes to the development of more accurate life prediction models for gas turbine blades, ultimately enhancing their performance and lifespan.

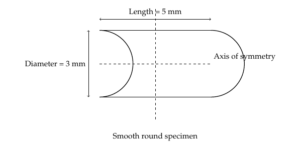

The material used in this study is DD3, a trademark of Beijing Institution of Aeronautic Material. Round bars with longitudinal axes within 5° of [0 0 1] were provided, from which standard smooth round specimens and notched round specimens (U-shape and V-shape) were machined. The smooth round specimen configuration is shown in Fig. 1, while the notched specimens have the same configuration with the addition of a notch in the middle of the bars, with geometries. A total of six notched specimens were studied.

Low-Cycle Fatigue (LCF) experiments were conducted at 520°C in air using an MTS-810 testing machine, with a temperature deviation in the gauge area maintained within ±2°C. All experiments were performed under load/stress control, with a testing frequency of 0.17 Hz. The testing procedure involved heating the specimens to 620°C, setting the testing machine to load/stress control mode, initiating the LCF testing, and continuing until specimen failure, while maintaining the temperature within ±2°C throughout the process.

The below figure and table presents the Low-Cycle Fatigue (LCF) records and results of smooth round specimens tested at 520°C. The table lists the specimen number, applied stress (\(\alpha\)max and \(\alpha\)min in MPa), and the average number of cycles to failure. Two specimens were tested for each case.

| Specimen No. | \(\alpha_{max}\) (MPa) | \(\alpha_{min}\) (MPa) | Average Number of Cycles |

|---|---|---|---|

| g-1 | 500 | 25 | >65700 |

| g-2 | 640 | 32 | >72633 |

| g-3 | 500 | -900 | 13423 |

| g-4 | 650 | -550 | 2041 |

| g-5 | 800 | -400 | 5334 |

The below table LCF Records and Results of Notched Round Specimens at 620°C, the LCF records and results of notched round specimens tested at 520°C. The table lists the specimen number, applied stress (\(\alpha\)max and \(\alpha\)min in MPa), and the average number of cycles to failure. Two specimens were tested for each case.

| Specimen No. | \(\alpha_{max}\) (MPa) | \(\alpha_{min}\) (MPa) | Average Number of Cycles |

|---|---|---|---|

| Notch 1 | 700 | 35 | 3639 |

| Notch 2 | 700 | 35 | 10804 |

| Notch 3 | 700 | 35 | 42860 |

| Notch 5 | 900 | 40 | 1404 |

| Notch 6 | 900 | 40 | 5083 |

| Notch 7 | 900 | 40 | 2609 |

The crystallographic slip theory is assumed to be applicable for nickel-based single crystals at 620°C. This theory is based on the relationship between the resolved shear stress (\(\tau\)) and resolved shear strain (\(\gamma\)) of the activated slip systems [3]. The resolved shear stress of a slip system \((\beta)\) can be obtained using the following equation: \[\tau(\beta) = \alpha : P(\beta)\] where \(\alpha\) is the stress tensor, and \(P(\beta)\) is a parameter that can be obtained from: \[P(\beta) = \frac{1}{2} \left( m(\beta) n(\beta)^{\text{T}} + n(\beta) m(\beta)^{\text{T}} \right)\] where \(n(\beta)\) and \(m(\beta)\) are the unit vectors normal to the slip plane and along the slip direction of the slip system \((\beta)\), respectively.

A power-law life model is assumed for the nickel-based single-crystal superalloys based on the crystallographic theory: \[\left(\frac{\tau_{\text{max}}}{2}\right)^2 = A N_f^b\] where \(\tau_{\text{max}}\) is the maximum resolved shear stress amplitude of all activated slip systems, \(A\) and \(b\) are parameters, and \(N_f\) is the fatigue life.

To consider the mean stress effect, a modification of the power-law life model is proposed: \[\left(\frac{\tau_{\text{max}}}{2}\right)^2 = A N_f^b \left( 1 – \left(\frac{\tau_m}{\tau_b}\right)^2 \right)\] where \(\tau_m\) is the mean resolved shear stress on the slip system corresponding to maximum shear stress, and \(\tau_b\) is the resolved shear stress corresponding to the ultimate tensile strength.

The parameters of the power-law life model are derived from the experimental results of specimens g-3 and g-4: \[\text{For specimen g-3:} \quad \left(\frac{\tau_{\text{max}}}{2}\right)^2 = 285.8 \, \text{MPa}\] \[\text{For specimen g-4:} \quad \left(\frac{\tau_{\text{max}}}{2}\right)^2 = 306.2 \, \text{MPa}\] The parameters are found to be \(A = 449.2\), \(b = -0.04888\).

The experimental results of specimen g-5 are used to validate the LCF life model: \[\left(\frac{\tau_{\text{max}}}{2}\right)^2 = 285.8 \, \text{MPa}\] Using the power-law life model, the predicted LCF life of specimen g-5 is: \[N_f = 5352\] which is in good agreement with the experimental result of 6234, with an error of 16.5

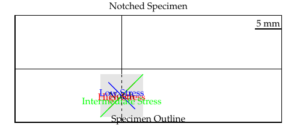

For notched round specimens, the finite element method (FEM) is used to provide the stress distribution [4]. The resolved shear stress contour plots and true stress versus strain relation of the notch region are obtained.

The LCF life model is validated by the experimental results of notched specimens using the same approach as for smooth round specimens. The model parameters obtained from smooth round specimens are used to predict the LCF life of notched specimens [5].

The following approach is employed to analyze the LCF life model prediction lives of notched specimens:

The stress versus strain relationship is obtained by tensile testing [6].

The region at greatest risk in different notch specimens is determined by crystallographic finite element analysis [7].

Based on crystallographic theory, the resolved shear stresses are computed corresponding to the maximum and minimum loadings of the greatest risk element [8].

The maximum resolved shear stress is calculated using: \[\tau_{\text{max}} = \max(\tau(\beta))\]

The resolved shear stress amplitude and the mean resolved shear stresses corresponding to the maximum resolved shear stress are calculated.

The LCF life model is used to predict the LCF life of notch specimens based on the parameters obtained from the smooth round specimens.

Mathematically, the LCF life model can be expressed as: \[N_f = \left( 1 – \left(\frac{\tau_m}{\tau_b}\right)^2 \right) \cdot \left(A \cdot \left(\frac{\tau_{\text{max}}}{2}\right)^{-b}\right)\] where \(N_f\) is the fatigue life, \(\tau_m\) is the mean resolved shear stress, \(\tau_b\) is the resolved shear stress corresponding to the ultimate tensile strength, \(A\) and \(b\) are parameters, and \(\tau_{\text{max}}\) is the maximum resolved shear stress amplitude.

The model parameters \(A\) and \(b\) are obtained from the experimental results of smooth round specimens, and the ultimate tensile strength is obtained from tensile testing. The mean resolved shear stress and maximum resolved shear stress amplitude are obtained from the finite element analysis of the notched specimens.

In this study, a low-cycle fatigue (LCF) life model was developed for nickel-based single-crystal superalloys at 620°C. The model is based on the crystallographic slip theory and takes into account the mean stress effect. The model parameters were derived from the experimental results of smooth round specimens, and the model was validated by the experimental results of notched round specimens. The results show that the LCF life model can accurately predict the fatigue life of both smooth and notched specimens. The model can also capture the effect of mean stress on fatigue life. The finite element analysis of the notched specimens shows that the model can be used to predict the fatigue life of complex geometries.

The LCF life model developed in this study can be used to predict the fatigue life of turbine blades made of nickel-based single-crystal superalloys. The model can also be used to optimize the design of turbine blades and to reduce the risk of fatigue failure. Overall, this study demonstrates the potential of using crystallographic slip theory to develop LCF life models for nickel-based single-crystal superalloys. The study also highlights the importance of considering the mean stress effect in LCF life modeling. Future work can focus on extending the LCF life model to other temperatures and loading conditions. Additionally, the model can be used to study the effect of other factors, such as oxidation and creep, on the fatigue life of nickel-based single-crystal superalloys.

1. Aslan, Ozgur. “Numerical modeling of fatigue crack growth in single crystal nickel based superalloys.” PhD diss., École Nationale Supérieure des Mines de Paris, 2010.

2. Marchal, Nicolas, Sylvain Flouriot, Samuel Forest, and Luc Rémy. “Crack-tip stress–strain fields in single crystal nickel-base superalloys at high temperature under cyclic loading.” Computational Materials Science 37, no. 1-2 (2006): 42-50.

3. Wang, Jialiang, Dasheng Wei, Yanrong Wang, and Xianghua Jiang. “A fatigue life prediction model based on modified resolved shear stress for nickel-based single crystal superalloys.” Metals 9, no. 2 (2019): 180.

4. Xu, Lianyong, Lei Zhao, Zhifang Gao, and Yongdian Han. “A novel creep–fatigue interaction damage model with the stress effect to simulate the creep–fatigue crack growth behavior.” International Journal of Mechanical Sciences 130 (2017): 143-153.

5. Wang, Rongqiao, Bin Zhang, Dianyin Hu, Kanghe Jiang, Xinyi Hao, Jianxing Mao, and Fulei Jing. “In-phase thermomechanical fatigue lifetime prediction of nickel-based single crystal superalloys from smooth specimens to notched specimens based on coupling damage on critical plane.” International Journal of Fatigue 126 (2019): 327-334.

6. Wang, Run-Zi, Ji Wang, Jian-Guo Gong, Xian-Cheng Zhang, Shan-Tung Tu, and Cheng-Cheng Zhang. “Creep-fatigue behaviors and life assessments in two nickel-based superalloys.” Journal of Pressure Vessel Technology 140, no. 3 (2018): 031405.

7. Zhao, L. G., N. P. O’Dowd, and E. P. Busso. “A coupled kinetic-constitutive approach to the study of high temperature crack initiation in single crystal nickel-base superalloys.” Journal of the Mechanics and Physics of Solids 54, no. 2 (2006): 288-309.

8. Bouvard, J.L., Gallerneau, F., Paulmier, P. and Chaboche, J.L., 2012. A phenomenological model to predict the crack growth in single crystal superalloys at high temperature. International journal of fatigue, 38, pp.130-143.